Cobot Takeout System for Shuttle Machines

NPE2024: Proco Machinery upgrades its Robopik bottle takeout system for shuttle blow molders with the addition of a collaborative robot.

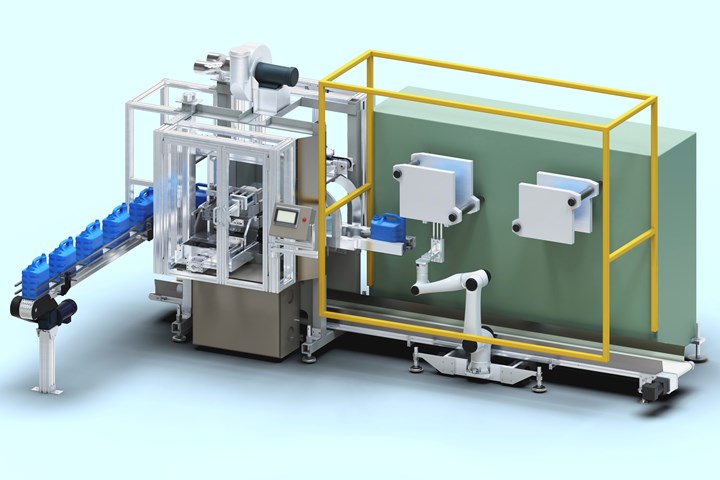

Updated Robopik bottle takeout system from Proco Machinery substitutes a versatile cobot for older fixed automation. Source: Proco Machinery

The next generation of Proco Machinery’s Robopik bottle takeout system is distinguished by its use of a jointed-arm collaborative robot (cobot), said to offer greater flexibility and adaptability than older fixed automation. The Robopik, designed for unloading and deflashing containers from shuttle blow molders, can be reconfigured easily to handle different types of products and adapt to changing production requirements, Proco says. The magnetically coupled cobot is said to also unload products faster and with greater accuracy than previous systems. The new system can handle delicate or irregularly shaped containers and minimize the risk of damage or defects.

It also features built-in safety features such as collision detection, emergency stop mechanism and protective barriers. Advanced connectivity enables seamless integration with other “smart factory” (Industry 4.0) technologies.

Related Content

-

End-to-End Quality Management For Aseptic PET Beverage Bottling

Sidel introduces Qual-IS comprehensive quality system to merge all QC activities in PET aseptic beverage bottling, from the preform blowing to laboratory management.

-

Second-Generation Plasma Surface Treater

New units built with new materials for system components that have proven to be more resilient.

-

Athena Controls Emphasizes Customization: Buy Just What You Need

At NPE, 60-year-old Athena reintroduces itself as a vendor of standard control platforms customized for maximum utility and economy.