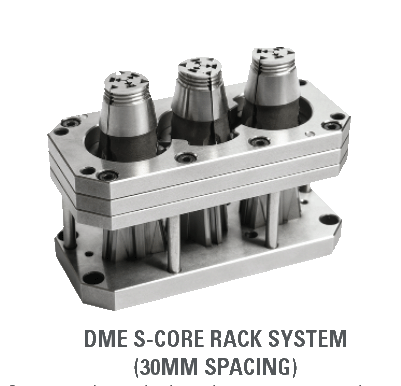

Collapsible Core Promises Long Service Life, Flexibility

DME's S-Collapsible cores can be configured as small as 6 mm or as large as 400 mm.

DME says its S-Collapsible core’s multiple segment configuration allows the system to be as small as 6 mm or as large as 400 mm. Besides rounds, different geometries, including ovals and squares can be incorporated into the S-Cores. Multiple cores can be integrated into one set of retaining plates to reduce spacing in between the units. Each core incorporates protective stops to prevent the folding segments from touching each other even if it has over traveled. DME will be exhibiting at (Sept. 21-23; Donald E. Stephens Convention Center, Rosemont, Ill.)

DME’s S-Collapsible cores come in multiple configuration formats.

Related Content

-

Three Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

-

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

-

Design Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.