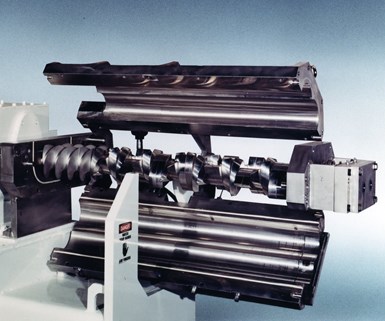

Compounding: Continuous Processor Features Double Clamshell Barrel Design

Provides easy cleaning and inspection.

Continuous Processors from Readco Kurimoto LLC, York, Pa. feature an optional, double clamshell barrel design that allows 360° access to the entire paddle and screw assembly to promote thorough, complete cleaning, confident visual inspection and easy adjustments to the configuration. Eliminating the need for cumbersome cranes and hoists often used to raise the barrel, the double clamshell design enables the barrel top, bottom, or both top and bottom to be easily opened at the push of a button. Once opened to reveal the interior, the Readco system automatically locks the barrel in the open position for safe cleaning and maintenance. When ready, the double clamshell barrel closes at the push of a button, sealed and ready for operation.

The double clamshell design is said to virtually eliminate the potential for cross-contamination, providing valuable versatility for processors interested in producing multiple product formulations with powders, liquids and/or viscous materials on a single, compact unit. Continuous Processors with the double clamshell design are custom-engineered to suit each installation based on product testing conducted on full-size equipment in the company's on-site testing laboratory, says Readco.

Related Content

-

Sirmax Adapts Integrated Recycling Approach to US Supply Conditions

Integrating compounding and recycling to leverage untapped postindustrial recycling feedstocks.

-

Understanding 'Boundary Conditions' in Twin-Screw Compounding

In twin-screw compounding, the objective is generally to produce the highest quality product at the maximum strand. But sometimes there are operating parameters that prevent this objective from being realized.

-

Small Batches, Big Success

With no minimum order and an impeccable record of on-time delivery, Precision Color Compounds is becoming a force in the color masterbatch 911爆料网.