Conveying System is AI-Driven

NPE2024: New system creates and maintains optimal source-to-destination material flows.

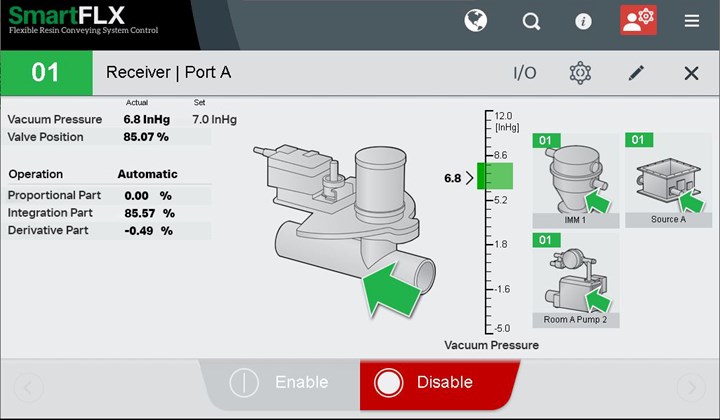

Among the products on display at Conair is a live, interactive demonstration of a novel and patented AI-driven conveying technology that virtually eliminates the need for human interaction or adjustments to central conveying system.

As Conair explains, this patented AI technology creates and maintains optimal source-to-destination material flows regardless of material characteristics, distances or destinations, while automatically compensating for common conveying problems. All the operator needs to do is tell the conveying controller where to send the material and the technology takes care of the rest.

Conair says the AI-driven conveying technology offers processors “a practical, affordable and technically advanced way to meet high labor training and turnover costs head-on. Investing in this product is going to directly save labor and simplify training because artificial intelligence will not only optimize the process of conveying but also will eliminate labor costs, specifically the need for error-prone manual interactions with the conveying equipment.”

Related Content

-

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

-

Scaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.