Cooling Added to Compact Slide

NPE2024: CUMSA adds cooling to the Compact Slides (CS) line launched last year.

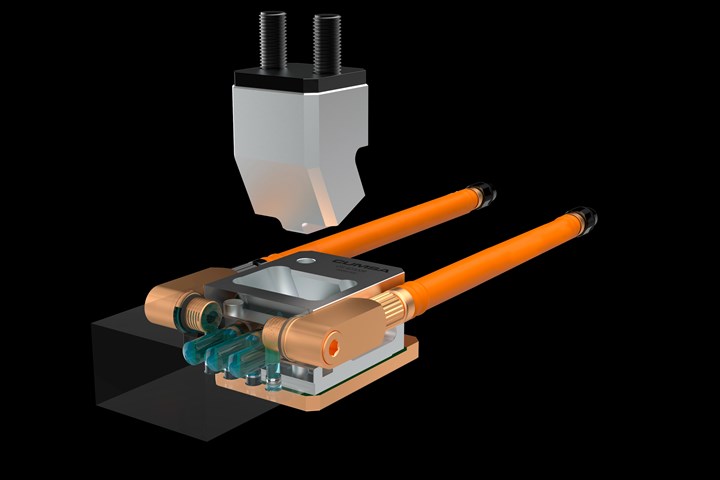

CUMSA is adding a cooling system to its Compact Slides (CS) with a floating insert, helping molders optimize the cooling process, lower cycle times, decrease energy consumption and improve plastic part quality. This cooling system design, combined with the insert, eliminates the need for a high-precision pocket. Available in three standard sizes — CR42, CR52 and CR62 — the cooled, compact slides feature an insert with predrilled holes to ease finishing the cooling circuit once the insert detail is machined. The three sizes have three, four and five predrilled holes, respectively.

Helping remove heat during molding, these cooling systems target difficult-to-cool areas in the CS line. The inserts have a 1/8 GAS-threaded hole on each side to connect the cooling hoses, which are sold separately, directly to the waterlines. The compact slides have strokes ranging from 9 to 22 mm, with ±0.05 mm horizontal movement to ease installation.

Predrilled holes ease finishing of the cooling circuit for CUMSA’s CS floating insert. Source: CUMSA

Related Content

-

General Polymers Thermoplastics to Further Expand Distribution Business

NPE2024: Following the company’s recent partnership buyout, new North American geographic territories are in its sight.

-

AI: The Next Big Thing in Plastics Processing

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

-

For Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.