'Dual Action' Purging Compound Accelerates Color Changes

NPE2024: Shuman Plastics’ Dyna-Purge Division launches Dyna-Purge L, extending its “3X technology.”

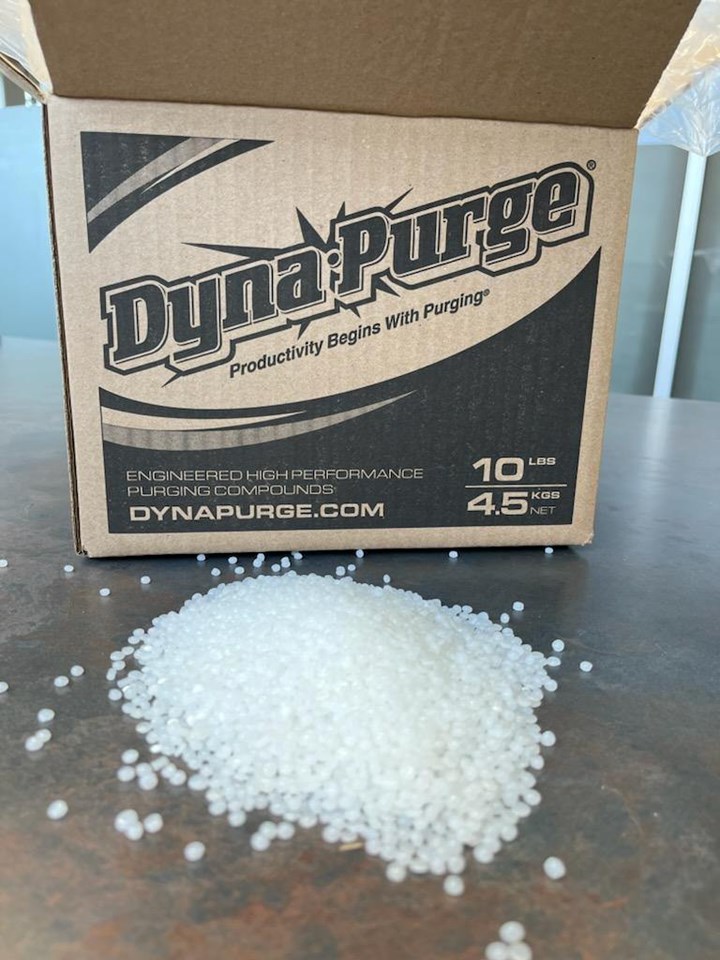

A new specialty “dual action” purging compound being highlighted by the Shuman Plastics’ Dyna-Purge Division is said to accelerate color changes for stack molds, high-cavitation molds, automated continuous molding environments and select extrusion applications, and further extends the company’s proprietary “3X technology.”

Dyna-Purge L is engineered for fast color or resin changes in demanding manufacturing environments best served through a lower viscosity product. This compound’s dynamic action is designed to work efficiently on the process boundary layers as well as expanding into negative flow and stagnation zones in the system. The L grade’s formulation is said to be safe and effective for removal of resin, color, carbon, additives and impurities without the introduction of abrasives or chemicals. The L grade’s “moldability” makes it essential for automated or closed environments.

The L grade was refined through rigorous field trials under actual processing conditions in order to earn commercial approval. This purging compound has been shown to be effective with all types of thermoplastics, and safely processed in the temperature range of 290°F-625°F (143°C-329°C). Like other Dyna-Purge products, L grade is also heat stable and suitable for shutdowns, startups, preventive maintenance and prior to manual cleaning. The amount of purge typically required is one to two times barrel capacity, though the actual amount may vary dependent upon age and condition of process equipment. Sample quantities are available at no charge.

Says company president Ken Shuman, “This compound’s attributes were specifically requested by a number of our clients. They asked us to combine specific characteristics, distinct from our other high-performance products. Our client-centered focus put us on a path to engineer this unique compound and it’s quickly becoming one of our fastest growing products.”

Related Content

-

Thin, High-Performance Nylon/PE Barrier Film for Thermoformed Packaging

Südpack’s Multifol Extreme film is well suited for greasy, protein-rich and frozen foods

-

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

-

Attending NPE2024 From the Perspective of a Molder

NPE2024 has come and gone, but before it’s completely in our collective rearview, Plastics Technology asked Rodney Davenport, vice president at injection molder CH3 Solutions, for a processor’s perspective on the big show.