Enhanced Digitization in Thermoforming

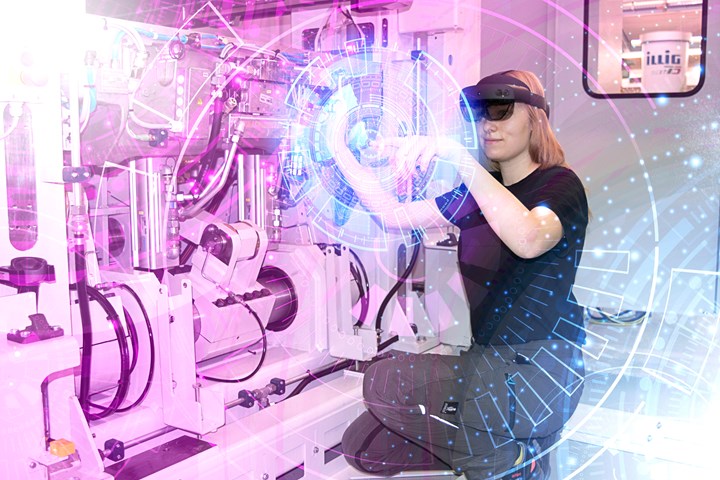

Illig’s Easy product family includes the newly developed Human Machine Interface, Illig Easy Touch.

The latest in digitization of thermoforming equipment from, featured at K 2022 trade fair this past October, is based around the new Illig Easy product family. This includes the newly developed Human Machine Interface, the Illig EasyTouch. with its 21” display and integrated access to the new web-based service and customer portal Illig EasyConnect. With this, Illig says, it focuses even more than before on the service needs of its customers with 24/7 high performance.

The key feature of Illig EasyTouch is the optimized user guidance attributed to the visual design of the user interface which is said to have been raised to a new level of user-friendliness. Ilig EasyTouch is now being installed as standard on every new Illig machine. Meanwhile the new web portal is said to offer customers a variety of digital tools to manage service communication with Illig quickly and centrally and to increase performance. According to Illig, the core of their digital development program is to technically bundles the processes along the entire production chain, to digitally network them and to make them intuitively operable.

Related Content

-

Interactive Training for Injection, Extrusion and Other Processes

Paulson has four in-booth stations demonstrating its various training solutions.

-

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

-

Ingenuity Is Part of This Former’s Name, and in Its DNA

Plastic Ingenuity started in a garage in 1972 and through a commitment to developing best-in-class products stands today as one of the largest custom thermoformers in the world.