Fakuma 2023: Boy to Showcase DC-Powered Press

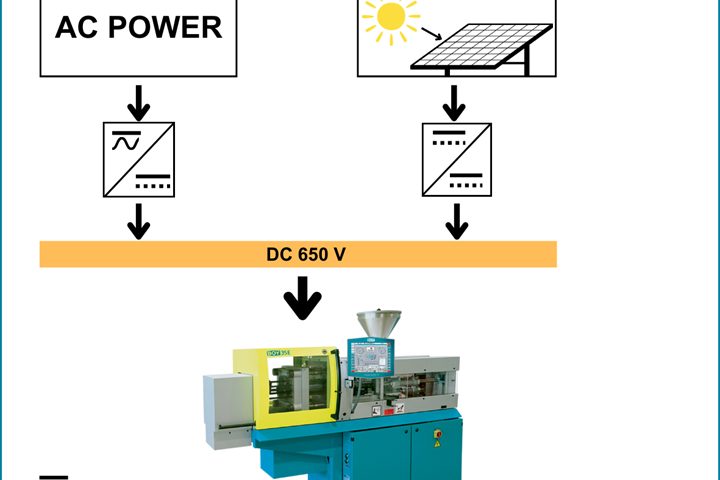

The German injection molding machine maker will display a BOY 35 E supplied by a DC network in support of direct, renewable energy powering of presses.

Addressing the changing nature of energy supply, as well as interest greater energy efficiency, Dr. Boy GmbH & Co. KG will display a BOY 35 E at Fakuma 2023 (hall A7 booth 7101) that is supplied directly by a DC network.

Boy notes that direct DC networks applied without transformation to AC-power offer many advantages for injection molders, including lower losses due to conversion; reduction in wire cross-sections and the number of wires; reactive power-free operation of the machines; elimination of interference filters; and better utilization of braking energy.

At Fakuma 2023, a BOY 35 E will feature power supply directly from a DC network.

Photo Credit: Dr. Boy GmbH & Co. KG

Related Content

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

-

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

-

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.