Continuous Mixer Supports Mechanical and Chemical Recycling Applications

NPE2024: Recycling solution works for a variety of situations including pyrolysis.

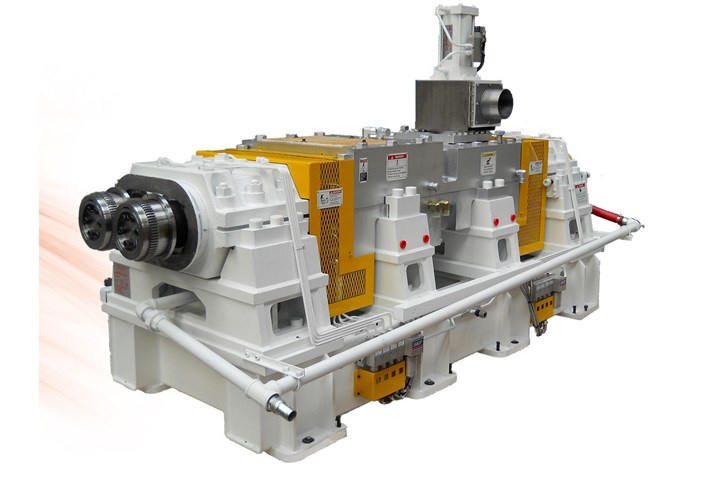

Farrel Pomini is displaying a product for both mechanical and chemical recycling systems, the Farrel Continuous Mixer.

The mechanical recycling system features include a large feed hopper for ingestion of irregularly shaped material, crammer options for low bulk density feeding, hard surface coatings for maximum wear, a grooved mixer feed section and a vent capture system.

The Farrel Pomini Continuous Mixer. Source: Farrel Pomini

Mechanical recycling on the Farrel Continuous Mixer is achieved with similar energy efficiencies of other applications at nominal production rates, according to the company.

As a complete recycling solution, the Farrel Continuous Mixer also serves as the primary stage of the chemical recycling process of pyrolysis to heat and melt plastic or rubber. Farrel pomini is a partner with , which has a patented pyrolysis system for recycling end-of-life tires.

In addition, a presentation is being given showcasing Farrel Pomini’s role in a pyrolysis process for plastics developed by . The process takes streams of different postindustrial and postconsumer waste to sort, shred, clean and prepare for a downstream conversion reactor for pyrolysis. The Farrel Continuous Mixer is utilized to melt the feedstock resin and homogenize it under specific temperature and pressure parameters.

Farrel Pomini is also highlighting capabilities in biodegradable plastics and recycled compounding at NPE. The Farrel Continuous Mixer’s low process temperature, short residence time and efficient rotor shear are useful for processing temperature-sensitive or prior heat-history applications. Successful experience processing PLA, PHA, PBS as well as recycled PVC and film scrap will be featured.

Dr. Peng Ye, applications development manager for Farrel Pomini, will present, “Novel Biocomposites Produced by the Continuous Compounding Process.” The presentation will cover work among partners Farrel Pomini, FPInnovations, West Fraser and Good Natured Products, to develop biobased and compostable compounds by combining wood-based and biopolymer materials.

Related Content

-

Film Extrusion: Boost Mechanical Properties and Rate of Composting by Blending Amorphous PHA into PLA

A unique amorphous PHA has been shown to enhance the mechanical performance and accelerate the biodegradation of other compostable polymers PLA in blown film.

-

Shredding Thin Film: How to Do It Right

While many processors recoil at this task, a little know-how in shredding equipment, processing, and maintenance should add the necessary confidence.

-

Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.