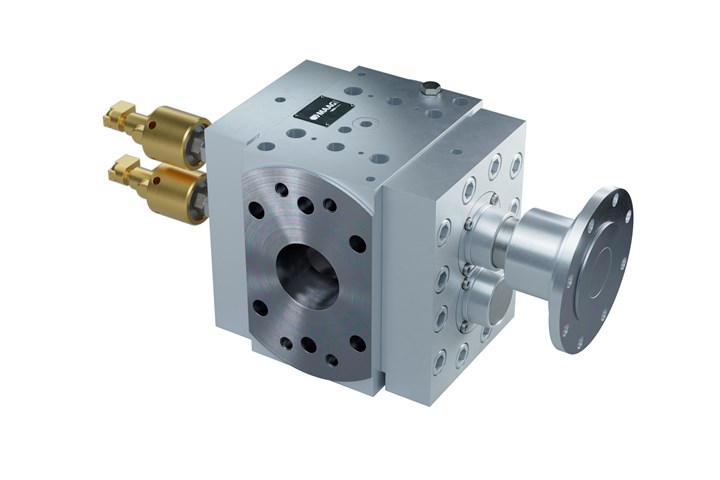

Gear Pump Suited for Elastomers

Provides gentle conveying of high-viscosity polymers through the system at both high pressure and low shear.

Maag has designed a gear pump specifically for processing elastomers. The extrexÔü is said to provide gentle conveying of high-viscosity polymers through the system at both high pressure and low shear. Maag will show the unit at the , September 21-23, Rosemont, Ill.

The compound is conveyed with a constant, precise flow even at high discharge pressures. Maag says this is a critical feature when processing extremely dry or sticky compounds, where former pump generations reached their limits due to scorch. As a result of reduced internal friction, the pump reportedly is highly efficient and extremely durable.

Related Content

-

The Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

-

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so the barrel appears to be turning clockwise around a stationary screw.

-

Part 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.