High-Efficiency Stabilizer for Aliphatic Nylons

Brüggemann’s Bruggolen TP-H1804 designed for use at continuous temperatures between 320°F-to-374°F

A new heat stabilizer masterbatch for aliphatic nylons is said to provide longer service life at high temperatures. Bruggolen TP-H1804 from Brüggemann is designed for use at continuous service temperatures between 320°F and 374°F. It complements Bruggolen TP-H1805 which stabilizes reinforced nylons at temperatures above 392°F. Supplied in granular form, this additive concentrate can be dosed very precisely, and thus in a very targeted manner.

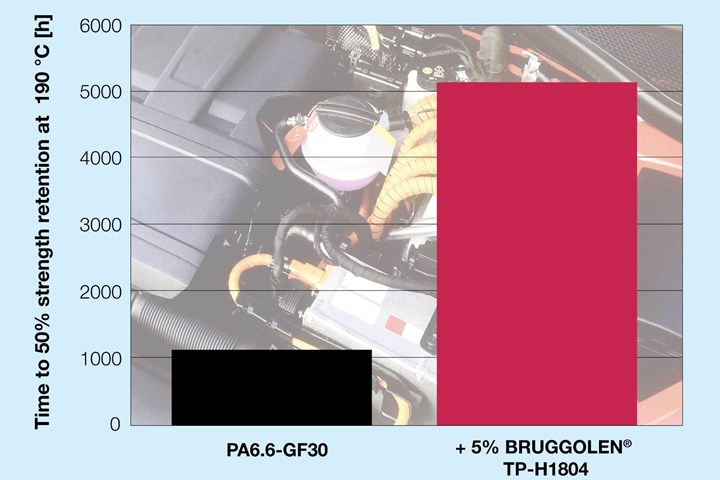

As “best in class”, according to the company, Bruggolen TP-H1804 significantly outperforms previously available copper salt-based stabilizers in terms of maintaining mechanical properties. For example, the tensile strength of a glass fiber reinforced nylon 66 with the addition of 5% is still over 50% of the initial value after 5,000 hours of heat ageing at 374°F; the un-stabilized material barely reaches this limit at 1,000 hours. At 338°F, thanks to its outstanding efficiency, even 2.4% is sufficient to exceed the 5,000-hour mark. As such, Bruggolen TP-H1804 is a product which, through its flexible dosing capability, allows molded component service life to be adapted to expected thermal loads.

Related Content

-

Polymer Science for Those Who Work With Plastics: Why Entanglements — Not Just Molecular Weight — Drive Plastic Performance

Ever try running your fingers through tangled hair? Yeah … that’s not fun, but that’s what happens at the molecular level when polymer chains reach the right length. They wrap around each other, intertwine and … get stuck — and those tangles are the real reason plastics perform the way they do.

-

Polymer Science for Those Who Work With Plastics: Molecular Weight — What It Is and Why It Matters

Molecular weight might seem like an abstract concept, but it plays a crucial role in determining the behavior of plastics during processing and in their final applications.

-

Polymer Science for Those Who Work With Plastic — Part 1: The Repeat Unit

What are the basic building blocks of plastics and how do they affect the processing of that material and its potential applications in the real world? Meet the repeat unit.