High-Torque Twin Takes Aim at High-Volume Operations

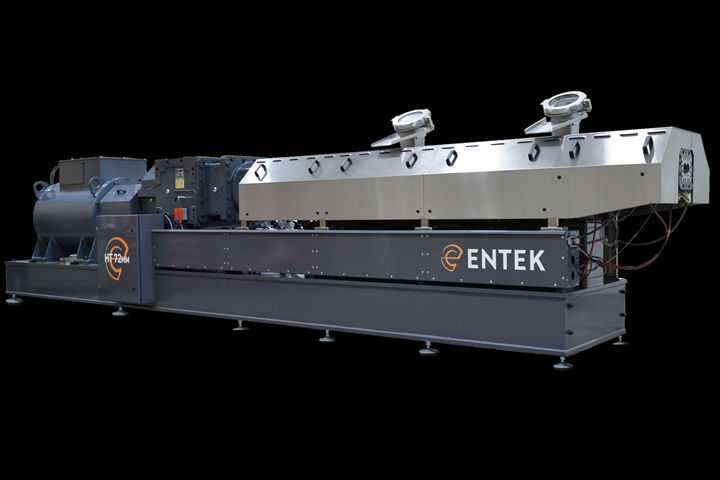

72-mm machine—first in a series—targets high-output commodity and masterbatch compounding applications.

ENTEK Extruders will be distributing literature at the upcoming a series of new products aimed at compounders, including a 72-mm co-rotating twin-screw that is the first in ENTEK’S HT (high-torque) series.

According to the company, the new extruder reportedly delivers the industry’s highest free volume of 1.61 Do/Di at 18 Nm/cm3 torque density, and—depending on the formulation and other factors—can operate at rates up to 10,000 lb/hr.

Photo: Entek Extruders

The target markets, not surprisingly, are high-output commodity and masterbatch compounding, an area that ENTEK previously has not served. In these applications, compounders typically run medium-to-large batch production sizes, and high production rates are particularly critical. And they typically run on a 24/7/365 basis. The machine features an oversized motor and is also said to be well suited for other applications that are torque or power limited.

Related Content

-

ICYMI: March Roundup

Still catching up post-PTXPO? Whether you attended the show or not, there were bound to be some must-read articles that may have slipped past you. Catch up on what you missed.

-

LAST CHANCE! Register Now for Plastics Technology Expo (PTXPO)

The third iteration of the event takes place March 18-20 in Rosemont, Illinois, providing three days of exhibits, technical education and professional networking.

-

Looking to Run More Regrind? PTXPO Workshop Tackles How

When it comes to making injection molding operations more sustainable, the lowest hanging fruit is the use of regrind, but that doesn’t mean it’s not without challenges.