Hot Runner Nozzle’s Cable Location Shifted

Hasco has extended its Vario Shot nozzle range and optimized its cable location.

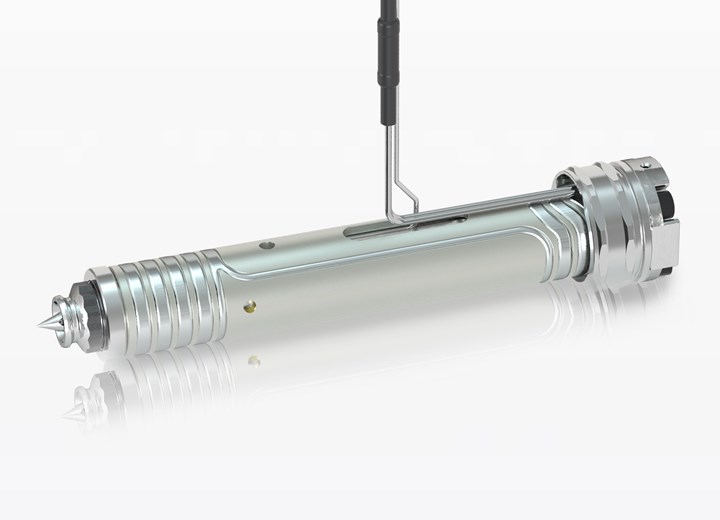

Hasco has expanded its line Vario Shot hot runner nozzles and developed a version where the cable outlet has been moved to the middle of the nozzle, relocating it outside the hot half in the nozzle retainer plate.

From a maintenance standpoint, this optimized cable location allows the heater to be easily replaced while the mold is in the press. In the case of multi-cavity hot runner molds or needle valve applications, processors will no longer need to dismantle the hot runner and remove the needle during service. Hasco notes that the hot runner nozzle’s thermocouple can be replaced from the parting plane. Through a strategically placed groove in the heater’s brass body, the thermocouple can be easily dismantled and mounted again.

Hasco has shifted the cable location for its Vario Shot hot runner nozzles, easing maintenance.

Related Content

-

Interchangeable Needle Valve Pre-Chamber Simplifies Hot Runner’s Maintenance

Hasco’s Vario Shot Xgate features an interchangeable needle-valve pre-chamber to lower the cost and difficulty of maintenance.

-

End Ring Valve Gate Optimizes Multicavity Application Injection Molding

The EYEgate HRS features a specially designed pin guide system engineered to ensure permanent pin-gate alignment to significantly enhance the end ring’s durability.

-

Hot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.