Injection Molding Machines Add Industrial IoT Service

Shibaura Machine says machiNetCloud provides users with secure, remote access to real-time machine data.

Share

Shibaura Machine, formerly Toshiba, a global supplier of injection molding machines, machine tools and die-casting machines, has launched the machiNetCloud industrial IoT service, giving users secure, remote access to real-time machine data.

Using remote access, authorized users and third-party vendors can monitor machines remotely and access data, enabling them to quickly respond to potential issues with a technician or spare parts. Shibaura says machiNetCloud can automatically alert third-party technicians and internal users by email and SMS.

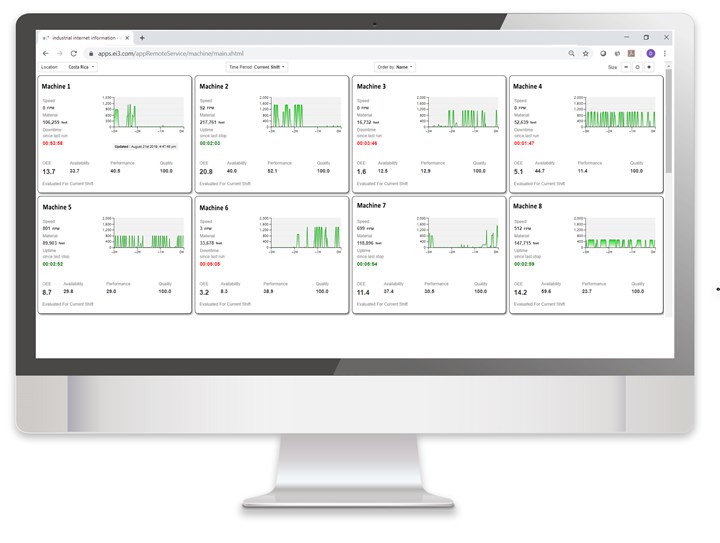

machiNetCloud features an intuitive customer portal, providing users with a suite of applications for reviewing key performance indicators. The program also automatically captures, analyzes and tracks machine downtime, helping users maximize overall equipment effectiveness (OEE) and calculate plant productivity. In addition to tracking downtime, the system offers real-time condition monitoring, historical performance and production analytics, as well as applications for managing quality, production recipes, energy usage and more. machiNetCloud is the first offering from Shibaura’s new Digital Services Div.

Shibaura’s new machiNetCloud IIoT service gives users secure, instant, remote access to key performance indicators. (Photo: Shibaura Machine)

Related Content

-

PTXPO Recap: Smarter Resin Drying & Conveying Automation

Check out what you missed on the PTXPO show floor. In this video, Editorial Director Jim Callari breaks down how AI is changing the game in plastics manufacturing.

-

How This Custom Compounder Leverages AI to Drive Innovation, Sustainability

Alterra has stepped up its cutting-edge Industry 4.0 technology with its own AI platform to further increase its efficiencies.

-

Production Monitoring Automates Molder’s Planning, Operations

DCT saves 60 man-hours per week by shifting from paper records and discrete spreadsheets to a shared, automatic production monitoring platform.