Injection Molding Networking Platform Adds Mold Transfer Software

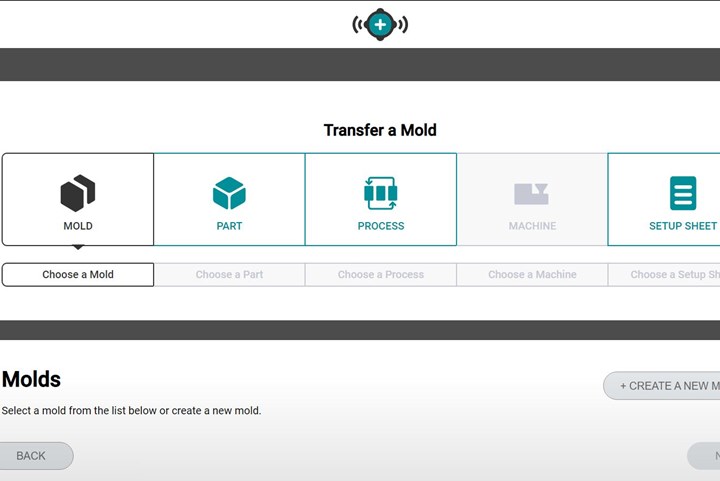

RJG says the new Mold Transfer software allows users to generate machine-specific setup sheets, recommend compatible machines and more.

The Hub for Mold Transfer from RJG allows users to easily move molds by automatically generating machine-specific setup sheets, recommending compatible machines and providing a database to store and share part, mold and machine documentation across an organization.

Noting that pairing a mold with the wrong machine can impact part quality, create inefficient processes or even damage a tool, RJG says Hub for Mold Transfer ensures proper mold and machine matching.

The program’s features include:

- Facility asset database for machines, molds, parts and materials

- Mold match recommendations for fit and capability

- Universal process sheet database

- Machine specific setup sheet database

- Automatically generated, machine-specific setup sheets

- Revision history

The Hub platform connects RJG’s CoPilot process monitoring systems to a single interface, allowing users to access plant information remotely and use that information to make data-driven decisions, increase visibility, decrease liability and improve operational efficiency.

The platform comes in four packages—Hub Mold, Hub Process, Hub Sim, Hub +—with varying price points. In addition to Mold Transfer, the Hub has a Process Analytics software allowing molders to view historical process data; audit reports for process changes; create plant-wide summary reports; generate plant overview dashboards; and review process statistics. In the future, RJG says the Hub will add Simulation Support software in the future.

RJG’s new Hub Mold Transfer software assists molders in the movement of tools.

Related Content

-

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

-

Use These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.

-

Injection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.