Large Scale 3D Printer Offered by Plastics Processing Machinery Company KraussMaffei

KraussMaffei launches PowerPrint, for product sizes up to 10 square meters.

KraussMafffei's powerPrint, announced at last year's K Show, is now available for purchase. KraussMaffei is also offering print-on-demand service. Since being introduced at the the trade show, the printer has been tested on a variety of fiber-reinforced and composite materials.

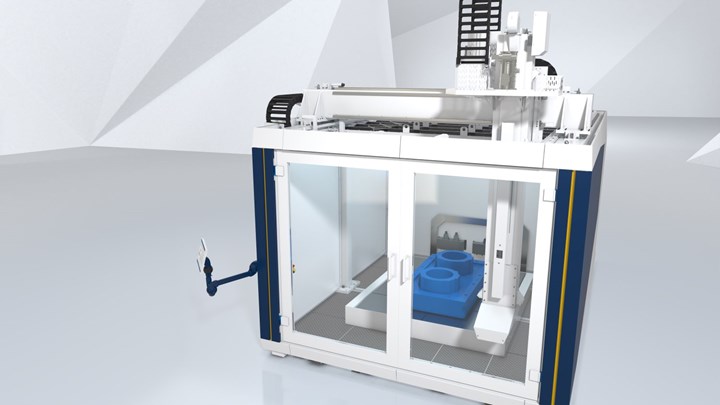

The powerPrint large scale 3D printer.

Photo Credit: KraussMaffei

PowerPrint uses thermoplastics in granulate form and extruder-based pressure build up. The printer offers an output rate of up to 30 kg/hr (66 lb/hr) and can produce components up to 2 x 2.5 x 2 m (6.6 x 8.2 x 6.6 ft.), without manual intervention, at temperatures up to 350° C (662° F). Print jobs can be changed quickly thanks to vacuum-fixed printing plates. A specially developed human-machine interface ensures intuitive and simple operation of the device.

According to KraussMaffei the powerPrint is suitable for all industries that require large-format objects with consistently high product quality, such as tool and mold makers, packaging and logistics, and the automotive industry.

Customers who want to try out powerPrint production can opt for print-on-demand service. As part of this service, applications are designed to customer specification and technical possibilities and then printed, with KraussMaffei also handling post-processing. Examples of implemented print-on-demand products include a molding tool for a vacuum infusion process, a sand casting mold, and a charging column.

Related Content

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

-

Insight Polymers & Compounding Unveils New Conductive Products Line

The new conductive products line will also be produced for injection molding and extrusion.

-

BMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).