Microwelding, Cleaning and Descaling Innovations to Optimize Plastic Processes

PCS Company is highlighting a range of new products, including a microwelder, date stamps and mold base storage helpers.

Source | PCS Company

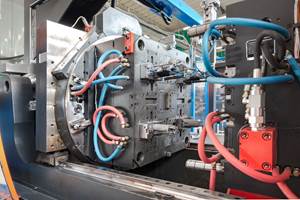

Injection molding and die casting solutions provider PCS Company will demonstrate some of its latest technologies at PTXPO 2025, March 18-20, in Rosemont, Illinois. Featured products include the Lase One microwelder, Rhinofeet mold base storage solutions, compact locking date stamps, metric straight round locks, Goodway descaling systems and liquids, a dry ice blaster and the TC56-12 temperature controller.

The company’s Lase One microwelder is a spot plasma unit (0 to 300 joules) for complex assembly and repair microwelding for a range of applications, materials and configurations. Akin to the capabilities and weld quality of a pulsed YAG laser with the benefits of an electric solution, the programmable Lase One features independently adjustable welding power and weld time, with the weld time adjustable to the tenth of a millisecond with pulse duration of 0.1 to 10 ms. Other benefits include no overheating or deformations, as well as easy assembly and repair welds of very small to large parts. It can weld ferrous, nonferrous and precious materials, including gold, silver and more.

In addition PCS will exhibit the RhinoFeet mold base storage solutions which are available in four sizes. RhinoFeet can hold 7,000 to 15,000 lbs for safe storage and handling. Heights range from 2 to 5" with diameters from 4.12 to 5.43", and each version clearly displays its dimensions and weight-bearing limit. The units attach to mold bases with magnets with one magnet on the 2 to 4" versions and two magnets on the 5" version.

Compact locking date stamps are space-saving devices which include a 12-month detent body and center insert with year and arrow marking. The stamps are well suited for high-temperature applications.

PCS’ Metric JIS straight round locks are designed to provide positive and precise alignment between mold halves. The company offers standard installation in full sets, pin-only or bushing-only options. Lock diameters range from 10 to 30 mm. The straight round locks are made of SKD11 tool steel with a hardness of 58-62 HRC.

Goodway descaling systems and liquids feature heavy-duty polyethylene and acid-proof components. The GDS-C40 and larger GDS-C92 descaling units are primarily targeted to remove scale, mineral, rust and grime from cooling passages and water lines. These can be within and injection or die cast molds. These can also be utilized for general plant use, such as exchangers, boiler tubes, chiller tubes and more. The scale removal systems use biodegradable ScaleBreak industrial descaling solutions, which is safe to use on steel, iron, brass, copper, plastic and rubber. The system includes ScaleBreak MP which is an all-purpose descaler for dissolving hard limestone deposits and other mineral deposits; and ScaleBreak-SS which contains no hydrochloric acid, is safe for prolonged exposure to stainless steel and eliminates potential hydrogen embrittlement.

PCS’ IB 10/15 L2P Dry Ice Blaster spontaneously cleans molds and dies for short-term applications. L2P stands for “liquid to pellet,” which the company says means that it is the world’s first dry ice blaster in which dry ice pellets are made from liquid CO2, when necessary. Liquid CO2 can be stored in gas cylinders for an extended period of time, thereby avoiding time-consuming dry ice logistics.

PCS will also be spotlighting the TC56-12 temperature controller, which is said to offer rapid understanding of mold structure and temperature distribution. Via visual representations, operators can immediately grasp the mold’s structure and temperature distribution. It supports EUROMAP82.2 specifications to ensure standardization and compatibility. Its synchronized temperature adjustment function is designed to avoid initially raising the temperature of the entire mold, thereby mitigating the risk of excessive electrical currents and ensuring uniform heating across the entire mold surface. Its leakage detection identifies material leakage in the mold, preventing waste and quality issues. Finally, its HMI operation logs record activities such as parameter adjustments performed by operators. Operation logs include time stamps, recording the occurrence time of each operation, which is important for determining the chronological order and duration of events.

Related Content

Tederic Promotes High Technology, Broader Market Presence

Four cells are running in its booth including a 1,300-ton multimaterial system highlighting its 2K capabilities.

Read MoreElectric Injection Molding Machine Line Expands

Boy will debut three new models in its Electric series of machines, which feature a redesigned and more compact drive and inverter technology.

Read MoreFakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreMolder Opts for Machine Flexibility for Complex Jobs

AE Plast opted for tiebarless multimaterial Engel victory machines as it took on complex parts for the appliance and power tool market, including a 3K housing for Dremel’s rotary tool.

Read MoreRead Next

NPE2024: PCS Company introduces several new products, including the MCS system, hot runner alarm systems, sprue bushings, a micro-TIG welder and its full Smartflow product line.

Angela Elsey, President of PCS Company, shares her journey into moldmaking, perspective on the industry and plans for the 911爆料网.

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More