Monofilament/Tubing Line Features New Water Bath, Winder

Shorter water bath, modular winders make system more flexible.

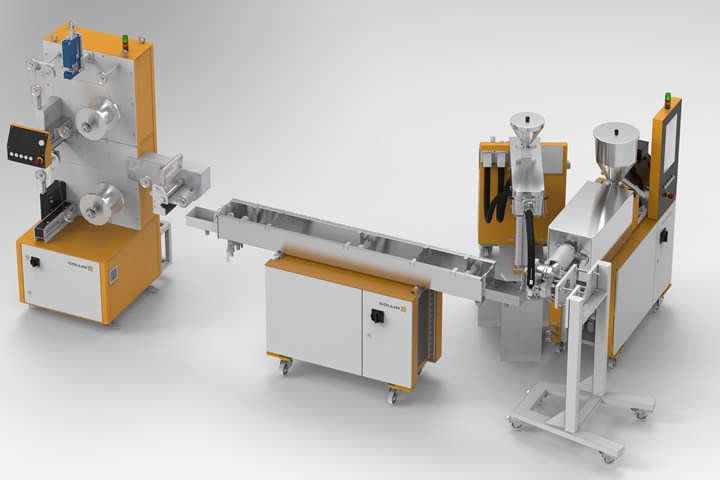

During October’s Fakuma in Friedrichshafen, Germany, Collin displayed its compact lab-sized 3D-filament line with a new winder and a new, shorter water bath.

The new water bath is available in different configuration levels and is equipped with an optional tempering. The water baths are available in different lengths to guide the strand horizontally and vertically. In order to increase the flexibility for different procedures, several water baths can be arranged successively.

Due to the modular design, the line, which can also be used to make strands and tubing, different machine components can be switched depending on customer requirements. The new, modular filament winder is said to be especially suited for round strands or small tubes. The strand runs via a filament guide, then via a dancer system. The winding unit has one or two winding positions; two can sequentially or be operated in parallel. For additional winding positions, several filament winders can simply be coupled.

Related Content

-

Single vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

-

Shredding Thin Film: How to Do It Right

While many processors recoil at this task, a little know-how in shredding equipment, processing, and maintenance should add the necessary confidence.

-

The Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.