New Melt Delivery and Control System Enables Design Freedom

Husky says its UltraShot Injection System liberates part design from the requirements of the injection molding process so that parts completed with other processes or post-mold assembly can now be produced in a single injection molding cycle.

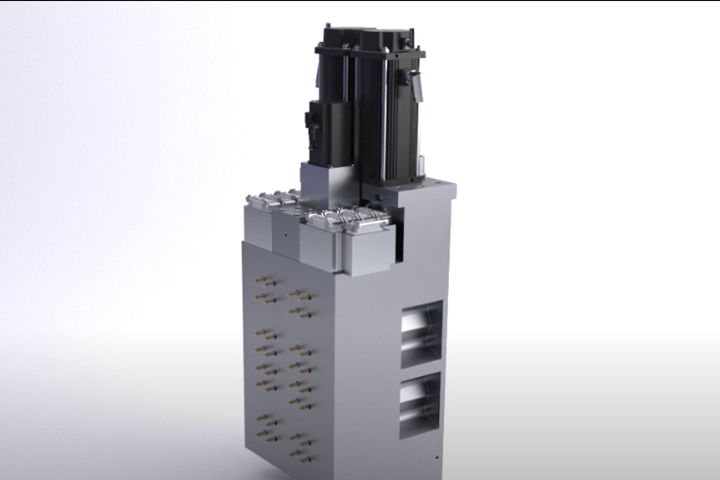

Husky’s new UltraShot Injection System pressurizes the resin near the cavities, reducing the influence of resin compressibility and shear, as well as thermal variations, on balance and part quality. This is different from a traditional hot runner where melt injection is decoupled from melt preparation. The company says the discrete injection circuit design is scalable up to 128 cavities, and that it overcomes traditional constraints of pressure, L/T (flow ratio) and difficult-to-mold resins. This further enables lightweighting, process time savings and greater flexibility in resin selection.

Husky says that compared to conventional hot runners, melt in the UltraShot Injection System experiences fewer high-pressure injection cycles, thus preserving the original resin properties. Lowering molded-in stress leads to better mechanical and optical properties in the molded part.

Part of that is due to the fact that Ultrashot technology utilizes precise, servo-controlled melt injection near the cavity. The resulting shorter flow length enables higher injection melt pressure and better control, since injection pressure is not reduced by compressibility in long melt channels. The technology is controlled by Husky’s Altanium mold controller offering integrated process control and monitoring.

Husky’s UltraShot Injection System is scalable up to 128 cavities.

Related Content

-

Scaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

-

How to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.

-

Hot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.