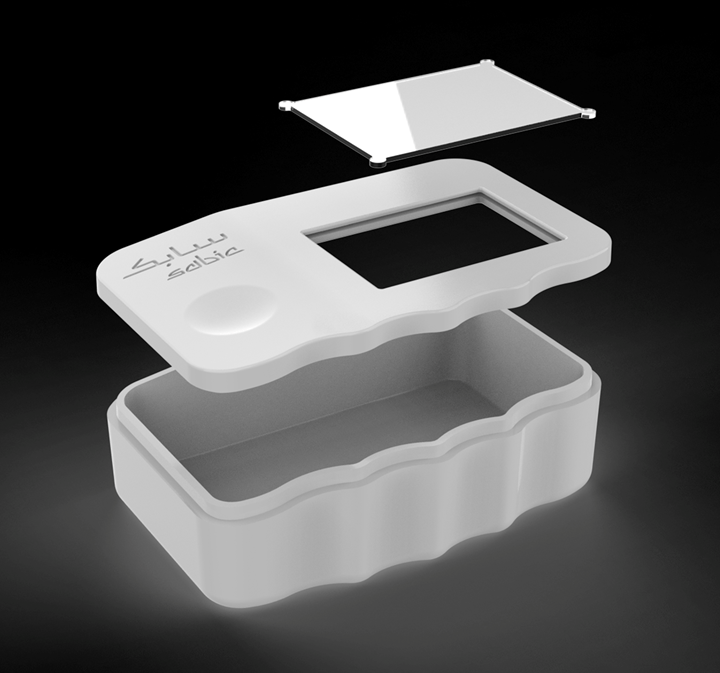

PC Copolymers for Chemically-Resistant, Thin-Wall Medical Devices

SABIC’s LNP Elcres CRX1314W and its biobased equivalent Elcrin CRX1314BTW boast distinct combination of properties for clear covers, screens and display lenses.

Two new PC copolymer resins for medical devices are said to offer a distinct combination of robust chemical and impact resistance, thin-wall transparency, dimensional stability and processability. Recently introduced by SABIC, they are offered as LNP Elcres CRX1314TW copolymer and its biobased equivalent, LNP Elcrin CRX1314BTW copolymer, which reportedly offers up to a 42% reduction in carbon footprint based on life cycle assessment (LCA).

In device applications such as clear covers, screens and display lenses, the CRX PC copolymer resins are said to overcome key drawbacks of incumbent PC resins and co-polyester resins when exposed to disinfectants or aggressive chemicals. Both grades feature limited biocompatibility according to ISO 109931 and coverage under SABIC’s healthcare product policy, which provides stringent management of change processes. Since SABIC’s first LNP Elecres CRX PC copolymer resins (which are opaque and custom colorable) were introduced at MD&M West 2020, the continued market need for chemically-resistant materials has driven the development of these innovative thin-wall transparent materials.

Related Content

-

Get Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

-

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.