Profile Die Design Software Simulates Cooling, Shrinkage

Enables use up of to 20 calibrators in the cooling system.

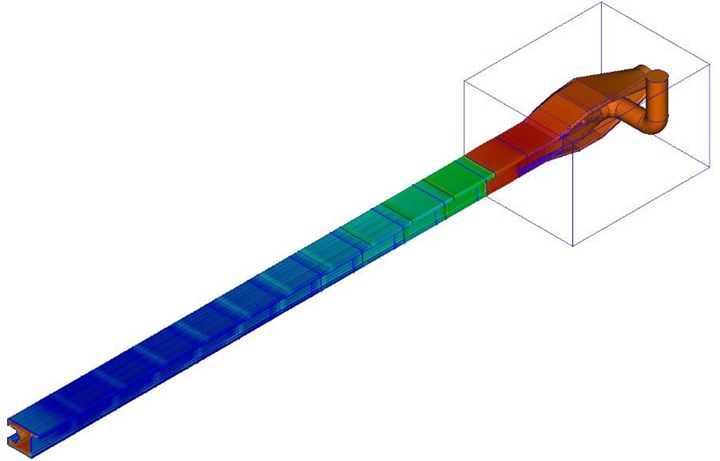

The new version of polyXtrue profile-die design software from is said to accurately simulate extrudate cooling and corresponding extrudate shrinkage in the complete cooling system. It included the following features:

- Twenty calibrators and sizers in the cooling system.

- Two different temperature zones between calibrators. One of the two temperature zones can be a wiper between a water tank and the next calibrator.

- Ten different temperature zones between the die exit and the first calibrator

- Ten different temperature zones are allowed after the last calibrator.

With the software, calibrator profiles can be different from the die exit profile. By gradually changing the shape of the profile in subsequent calibrators, the shape of the extrudate profile can be significantly modified after it leaves the die, allowing extrusion of complex profiles from relatively simple die geometries.

Die geometry files can be imported from SolidWorks, Inventor and Creo software. The new version allows users to import die geometries in native Creo file format. The die geometries in SolidWorks and Inventor file formats can also be imported as before.

Related Content

-

'Hybrid' Die Design Eliminates Weld Lines, Cuts Stagnation

NPE2024: Newest extrusion tool retains benefits of previous design and adds features to boost quality.

-

Crosshead Die for Elastomers Adjusts Easily

NPE2024: Mechanically actuated gum space adjustment requires only ordinary socket wrench.

-

New Rotary Die and Cam Lock Design for Tubing

NPE2024: New design enables quick and easy assembly and disassembly of the crosshead, and eliminates the socket head cap screws.