Recycling Line Boosts PET Melt Quality

At K Show and an Off Site Open House, BB Engineering demonstrated its innovations for PET recycling.

, a joint venture of and , presented a PET recycling line called Vacufil at October’s K 2022 Show in Dusseldorf.

Vacufil uses the liquid state polycondensation process for recycling PET. It combines large scale filtration and regulation of intrinsic viscosity. A key component is the patented Visco vacuum filter, which removes volatile impurities. Vacufil can be used for both post-consumer and post-industrial input materials.

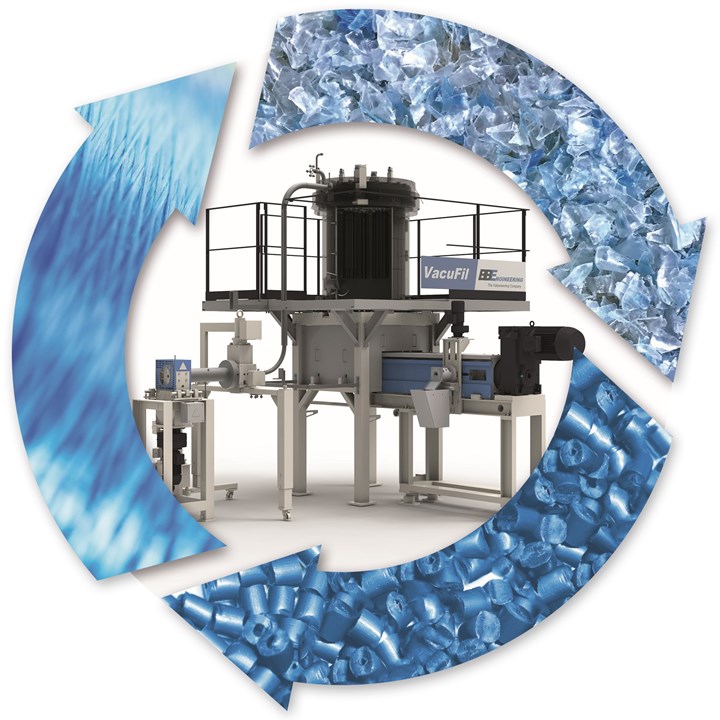

BB Engineering’s Vacufil integrated recycling plant.

Photo: BB Engineering

Vacufil is modular, and can be configured for downstream processes, including the BB Engineering’s own Variofil spinning plant. The Variofil produces a polyester yarn.

K Show attendees who went to an open house at BB Engineering during the trade fair saw this combined process in action. Its facility in Remscheid is less than 30 miles from Dusseldorf.

Related Content

-

Skipping the Pellet for Efficient Recycling in Molded Engineering Plastics Applications

AGS Technology leverages deep experience in molding with recycled engineering materials for automotive and heavy equipment parts.

-

Optical Sorting for Color Flexibility in Recycled Plastics

Aaron Industries added optical sorting to its operation, expanding capabilities to meet the color needs of customers.

-

Breaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.