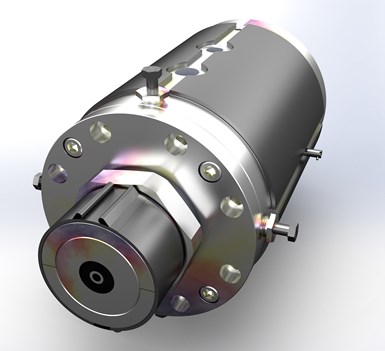

Spiderless Pipe Die Touts Material Savings

Capable of providing a finished extrusion with OD from 2 in.-15 in.

A new Spiderless Pipe Die from Guill Tool is said to provide increased material savings compared to conventional basket dies for pipe and tubing extrusions. In the design, polymer flows through a distribution plate very similar in design to a breaker plate. Guill describes this plate as a disc into which many small flow passages are machined in a randomized pattern. This is said to distribute the polymer flow evenly around the circumference of the die body.

Photo: Guill Tool

This new die is capable of providing a finished extrusion with OD from 2 in.-15 in. It’s offered in 4140 steel, or stainless with heat treating.

Guill says material savings are realized due to precision machining, its ability to do flow analysis, and its engineering and design capabilities, among other things.

Related Content

-

'Hybrid' Die Design Eliminates Weld Lines, Cuts Stagnation

NPE2024: Newest extrusion tool retains benefits of previous design and adds features to boost quality.

-

Bonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

-

Part 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.