System Simplifies Thread-Repair Insert Installation

NPE2024: C-Sert Manufacturing’s new installation system is designed to speed up the removal of damaged threads and the creation of a new pilot hole — 10 to 15 minutes per hole — with just four components.

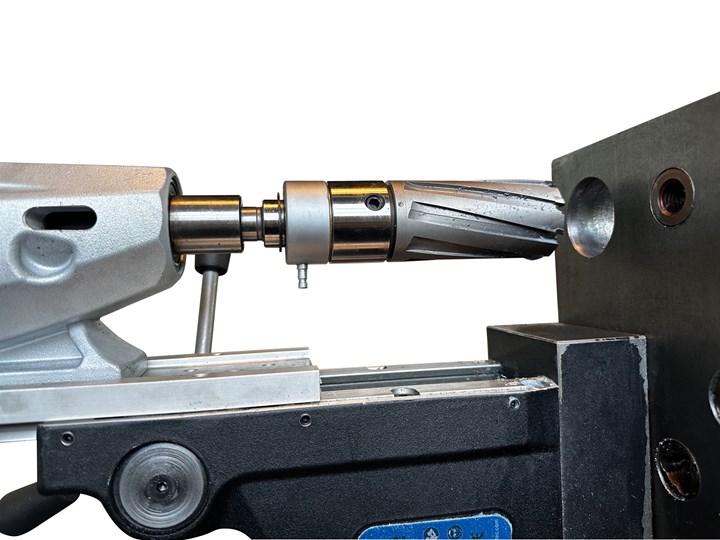

C-Sert’s installation system utilizes a 60-degree center to position the mag drill squarely on the platen hole. Source: C-Sert

C-Sert Manufacturing is introducing a new installation system for its C-sert thread-repair inserts, enabling fast, safe installation on injection molding machine platens. C-Serts are self-tapping inserts made from through-hardened S7 high-impact tool steel for the permanent repair of damaged platen holes, where frequent mold changes and production pressures can lead to stripped threads. C-Serts enable a permanent repair that’s guaranteed for the life of the press against thread wear, pullout and back-out. Self-tapping and self-aligning, C-Serts are designed to install straight.

The new C-Sert installation system can remove damaged threads and create new pilot holes in 10 to 15 minutes per hole. The system consists of four components, starting with a 29-lb German-made magnetic drill. Enabling one-person operation, C-Sert says the drill prevents injuries, minimizes downtime and eliminates the need for 100-lb magnetic drills or overhead cranes.

Next, annular cutters replace traditional drill bits, creating far lower tool pressure so the 29-lb mag drill can open large holes up to 1 ¾ inch. A 60-degree center positions the mag drill squarely on the platen hole, preventing misaligned drilling or drill placement, and the paste coolant replaces a mag drill’s traditional, gravity-fed coolant system. C-Sert says a teaspoon of the paste goes into the hollow annular cutter and melts as the cutter heats up, keeping the coolant on the cutting surface. The company notes that traditional gravity-fed liquid systems can’t accommodate vertical surfaces, such as platens.

In a release, C-Sert owner Carl Strom says his company is making the installation system available at cost for around $1,000, which he says is much less than the price of a single, large magnetic drill.

Annular cutters replace traditional drill bits for lower tool pressure. Source: C-Sert

Related Content

-

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

-

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

-

Breaking News From NPE2024

Here is a firsthand report of news in injection molding, extrusion, blow molding and recycling not previously covered.