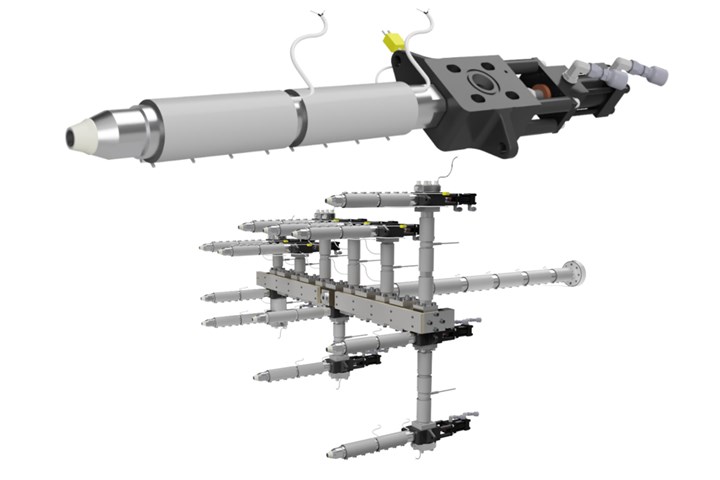

‘Universal’ Structural Foam Nozzles And Manifold Components

Wilmington now provides these components for all makes of structural-foam machines.

For the first time, Wilmington Machinery is now offering structural-foam nozzles and manifold components that are said to be “universal” for all structural-foam machines of any make. Previously, the company offered such components only for its own machines. The new Lumina products, all manufactured in-house, are available on the company’s and sold as assemblies or individual components.

The Lumina nozzle has a forged body with what are described as “generous flow characteristics” and variable nozzle length extensions. The forged nozzle housing is said to provide improved plastic flow compared with other nozzle types. It also reportedly costs less than comparable nozzles. The Lumina manifolds are provided with block-off plug provision to eliminate stagnant melt buildup. Spacers (manifold extensions) are available in various lengths to match the 6 × 6 in. grid pattern for nozzle placement.

Related Content

-

Process Monitoring or Production Monitoring — Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

-

Understanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.