Upgraded Collating System for Complex, Unstable Bottles

Sidel has improved its Cermex ProSelex flexible collating system, which is now faster, more compact and easier to change over.

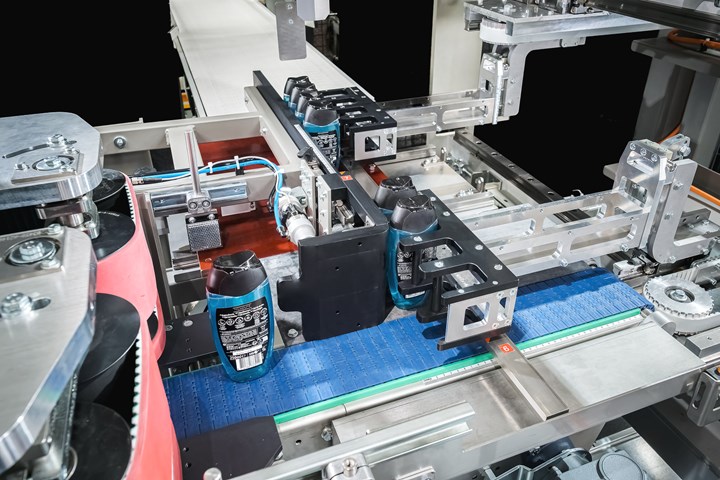

Faster but gentle handling of creative but unstable bottle shapes is claimed for the new generation of Cermex ProSelex collating system from Sidel. (Photo: Sidel)

At the Interpack show in Germany next month, Sidel will unveil the new generation of its Cermex ProSelex flexible collating system for complex, unstable bottles. This gentle, streamlined grouping device is designed to work with any type of case packer. Acting as an integrated module of a case packer that is receiving products upstream from a single lane, this device continuously pitches, collates and prepares the container batches before they are transferred and case packed. The newest version boasts higher speeds as fast as 300 bottles/min and a smaller footprint. It also offers simpler and faster changeovers, from 1 min for a new collation to 2.5 min for a complete bottle change. A small number of change parts is needed to adapt the system to a new bottle format.

According to Sidel, the system is a response to proliferation of customized bottle designs in creative shapes that add brand identification but lead to challenges in conveying and handling. Servo-driven gentle handling and continuous flow are said to prevent shocks and scratches to bottles, as well as product jamming and “shingling.”

Related Content

-

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

-

BMW Group Vehicle to Adopt 3D Printed Center Console

A vehicle coming to market in 2027 will include a center console carrier manufactured through polymer robot-based large-format additive manufacturing (LFAM).

-

Scaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.