Injection Molding

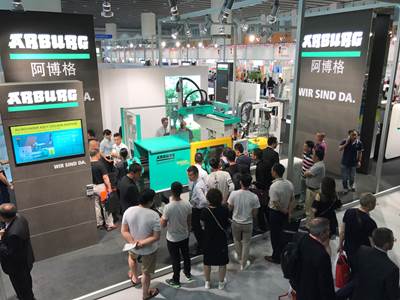

Three Straight Years of Record Results for Arburg

Arburg marked a third straight year of record turnover with growing contributions from Asia, as well as its newer large-tonnage and all-electric machine offerings.

Read MoreEngel Nears Completion of Capacity Expansion in Shanghai

As the company marks 10 years of large press production in Shanghai, it closes in on an expansion that will greatly expand capacity and max out the available land space.

Read MoreVIDEO: Liquidmetal and Plastics Molding

Beyond a process curiosity, Liquidmetal's technology could provide plastics molders a path to metal parts production.

WatchPut Out the Production Fire Once and For All

Plastics production rides a fine line when the goals of low scrap, high yields and sustainable, repeatable systems are being developed.

Read MoreHow Can UK Mfg. Respond to the Triggering of Brexit, Article 50?

With Article 50 now activated, Brexit isn’t something that may happen, it’s here and we now rely on the U.K. Government and economists to get the best deals for Britain.

Read MoreFemale-Led Injection Molder Certified by Women’s Business Enterprise Council

Imlay City Molded Products is one of the few female-owned and/or operated plastics molding companies.

Read MoreNew Process & Material Permits Big Weight Savings on Foamed Parts

New firm develops technology that offers weight reductions up to 65% for large injection molded polyolefin parts.

Read MoreMolder & Moldmaker Embraces Minimalist Tooling Philosophy

RenyMed’s niche consists of projects where it can offer not only molding, but help in designing and making the unique, compact, modular tools that are a company specialty.

WatchBlock Cavities and Keep Molding

It goes against conventional wisdom, but molding with blocked cavities can be done while maintaining quality with the help of appropriate in-cavity sensors and process-control software.

Read MoreIf Two Arms Are Better Than One, Are Four Better Than Two?

Robots with two main arms have proven useful in applications ranging from stack molds to IML to insert molding and performing a variety of post-mold operations. The concept has evolved to the point that a single robot chassis can have two kick assemblies with one or two arms apiece.

Read More