Injection Molding

The 5 M’s of Molding—Part I: Man (labor)

There are many areas in which personnel affect consistency and repeatability within a plastics operation.

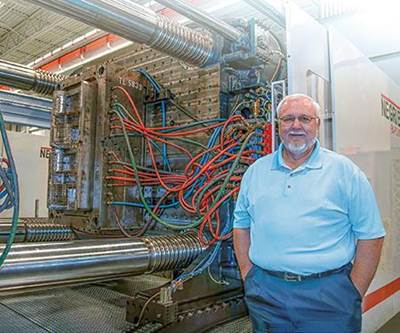

Read MoreCustom Molder Expands in ‘Leaps of Faith’

Who would embark on an $8.8 million plant expansion without new orders in hand? Someone who knows his customers very well.

Read MoreBeefier All-Electric Machines With Enhanced Control Features

Presses designed to dismiss the perception that all-electrics can’t handle larger, heavier molds.

Read More‘All-Purpose’ Screw for Injection Molding Handles a Wide Range of Polymers

A mixing section with replaceable dams is said to remedy the limitations of so-called “general-purpose” injection screws.

Read MoreLSR Developments in LEDs for Automotive and Street Lighting

LSR鈥檚 resistance to UV light and high temperatures allow direct contact to LED, while low injection pressure allows overmolding of sensitive parts.

Read MoreSo How Fast Can You Change a Mold?

A contest next month at a U.K. trade show will crown one molder king of the quick-change artists.

Read MorePlastics Pioneers Association Adds Four to Membership Roster

Group membership swells to 200+.

Read MoreWintec Adds All-Electric Line, Expands Sales Outside of China

All-electric 100- and 180-ton injection molding machines join two-platen presses in portfolio, while sales extend to ASEAN, Iran, Turkey and beyond.

Read MoreHot/Cold Injection Molding: Which Approach Is Best for You?

The hot-and-cold molding process gives molders a new tool to achieve top-quality esthetics or to fill challenging thin-wall parts. There are a number of options in heating methods, and this article discusses the ins and outs of each.

Read MoreHigh-Tech Molder Modernizes Its Fleet

EPC replaces older presses with its first all-electrics, in integrated cells from a single source.

Read More