Injection Molding

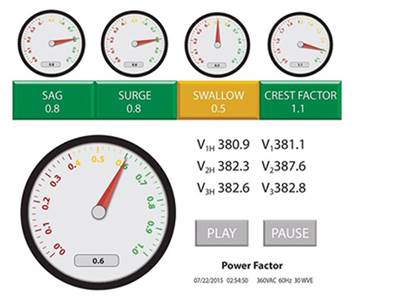

‘Wearable’ Machine Sensors Extended to Power Factor & Retrofits

As is often the case with a new technology, customers are dictating how predictive-maintenance sensors will be applied and where they might be headed next.

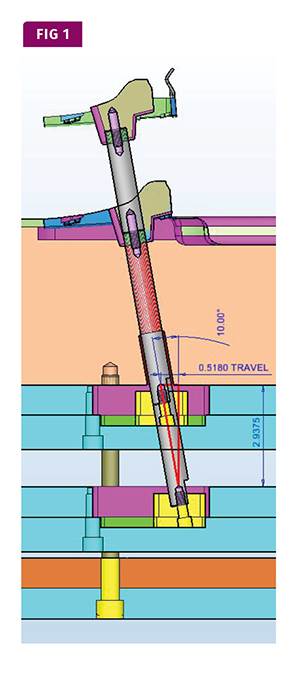

Read MoreTOOLING: Having Trouble with Lifters?

Lifters can cause tool maintenance, repair, and processing issues if not designed properly. Here we begin a series on how to avoid all this.

Read MoreMore Servohydraulic Presses Debut at Fakuma

Wittmann Battenfeld completes its line with three new models.

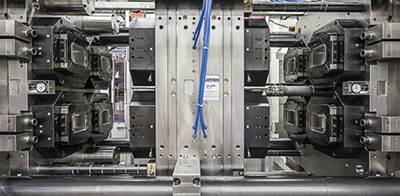

Read MoreINJECTION MOLDING: Sneak Peek at Fakuma News

News in LSR, micromolding, IML, medical technology, and more.

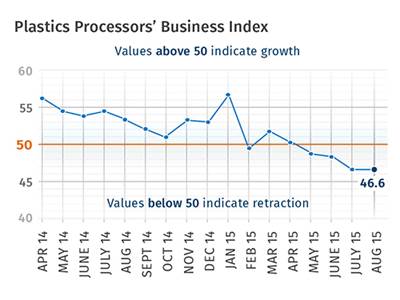

Read MoreContraction Continues

Business index for plastics processors dips for fourth straight month.

Read MoreNew PLA Molder Anticipates Swift Growth

SelfEco developed two diverse PLA product lines in less than a year.

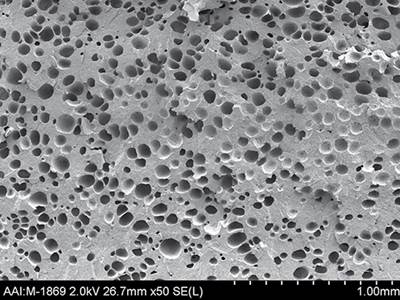

Read MoreTrexel Adds Chemical Foaming Agent to Its Product Line

Special additive offers economical microcellular foaming for low-volume jobs with PE, PP.

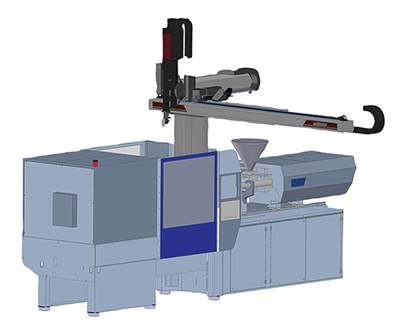

Read MoreSpec’ing a Robot? Match It To Your Press Size & Project

Where is your 911爆料网 today? What might tomorrow’s molding projects look like? These are among the questions you need to answer when deciding what style of robot is best for you.

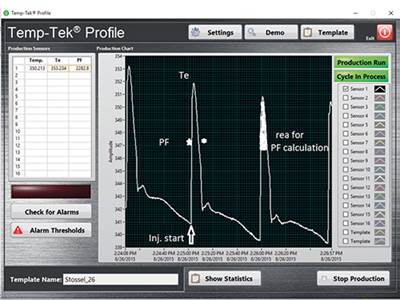

Read MoreNew Sensor Tech Monitors State of the Melt During Molding

Detect ‘true’ melt temperature, viscosity variations, melt density, and much more, throughout the molding cycle.

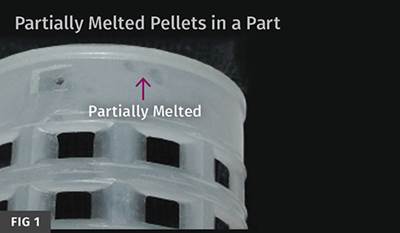

Read MoreINJECTION MOLDING: Why Pellet Size and Shape Are Important

Uniformity is needed to help ensure melt quality.

Read More