Injection Molding

RFID Boosts Production Efficiency For Bumper Molder

RFID technology significantly improves ‘error-proofing’ and productivity from molding to final fabrication.

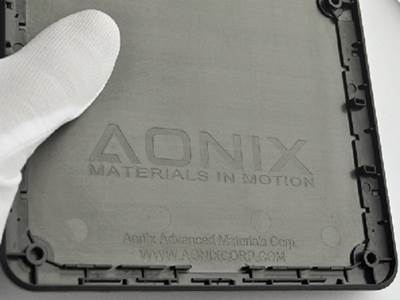

Read MoreTablet Computer Shell Demonstrates Thermoplastic Composite Process

Advanced materials and high-speed molding machines comprise a new turnkey system for thermoplastic composites.

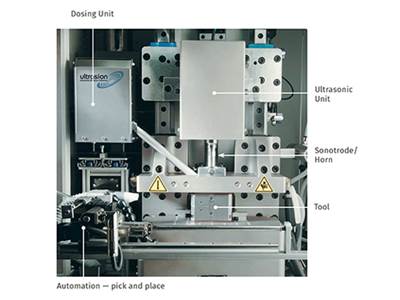

Read MoreMold Micro Parts with Ultrasonic Technology

New machine utilizes ultrasonic waves to melt plastics for micromolding, as opposed to the shear and conductive heating used in standard processes.

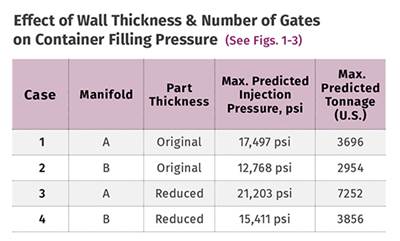

Read MoreINJECTION MOLDING: The Importance of Nominal Wall For Lightweighting Molded Parts

Establishing a nominal wall is one of the most important decisions an engineer makes when designing parts. Understanding how design changes will impact the manufacturing process is critical to ensure the part performs as expected.

Read MoreFEA Software Predicts Material Response to Repeated Snap Fits

Improved finite-element modeling accounts for viscoelastic response to multiple stress-strain cycles.

Read MoreCustom Molding Hourly Rates—It’s Up to You Now

Are you as eager as I am to see average machine-hour rates for custom injection molding, broken out by machine size, region of the country, and with or without operator or profit included?

Read MoreFormer Hoover vacuum injection molding plant on the block

Why did the “Largest Injection Molding Manufacturing Plant West of the Mississippi” wind up on the auction block?

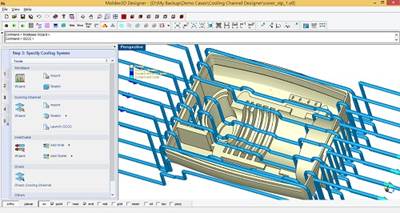

Read MoreTOOLING: Mold Simulation Software Gains Speed & New Functionality

Enhancements in simulating conformal cooling, hot runners, MuCell foaming, shrink/warp, and fiber reinforcements.

Read MoreNovel Tooling and Materials Highlight Thermoplastic Composite Advances

Conference showcases new developments in equipment and materials for more efficient production of automotive thermoplastic composites parts.

Read More