Stretch Blow Molding

Enhanced PET Stretch-Blow Technologies from KHS

KHS enhanced its Blowmax rotary reheat stretch-blow machine to meet demand for single-serve beverage bottles. It also developed what’s said to be the lightest half-liter PET bottle for still water.

Read MoreNew PET Machines & Pinch-Handle Technology

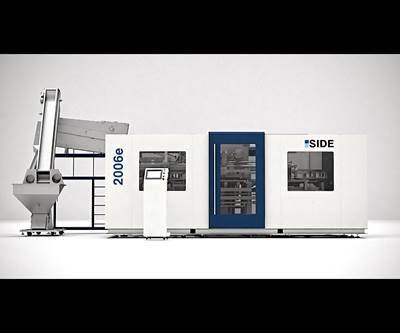

SIDE presents a new generation of PET stretch-blow molding machines for products from 250 ml to 10 L.

Read MoreOne- and Two-Stage PET Machines for Higher Productivity & Specialty Products

Five machines from Nissei ASB are stretch-blow molding: beer bottles, airline liquor miniatures, sports bottles, premium cosmetics bottles, and wide-mouth, hot-fill jars.

Read MoreInjection-Blow Molding Multi-Layer Barrier Bottles

Kortec hot-runner technology and an auxiliary injector convert a standard machine to three-layer co-injection blow molding.

Read MoreCompact Stretch-Blow Machine for Complex Bottle Shapes

New compact stretch-blow molding machine is suited to custom bottles with complex or “difficult” shapes.

Read MoreAmcor Launches First Commercial Container Using Its LiquiForm Technology

First commercial PET container from Amcor’s simultaneous stretch-blowing and filling process.

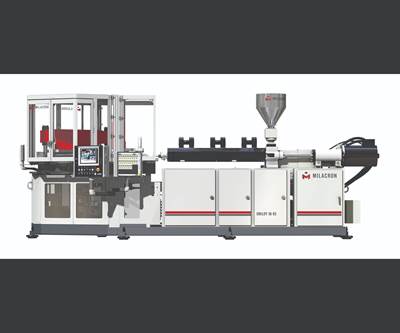

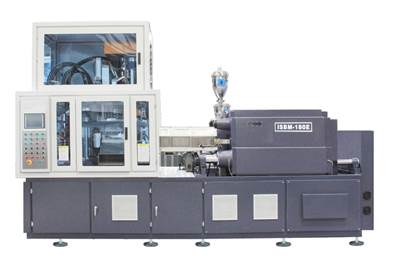

Read MoreNew Electric Machines for Injection-Blow & Stretch-Blow Molding

Clean, fast, and energy-efficient machines from Pet All Manufacturing.

Read MoreBlow Molding: New Buffer Integrates Bottle & Cap Molding with Filling Operations

SACMI combines PET bottle blowing, filling, capping, labeling in one machine; coordinates speeds of bottle and cap molding for integrated filling lines; and advances digital cap printing.

Read MoreBlow Molding: ‘Individual Mold Control’ for PET Reheat Stretch-Blow Machines

Agr International and KHS are offering independent control of individual PET bottle blowing stations.

Read MoreBlow Molding: Heavy-Duty Bottle Deflashers

A pair of high-impact bottle deflashers are designed for heavy-wall containers made of tough resins like PC and E-PET.

Read More