Pilot Plant to Produce Multipurpose Bioplastic from Soy Residue

Four Finnish companies in collaboration to develop the first process to produce compostable bioplastic from food and feed production side streams.

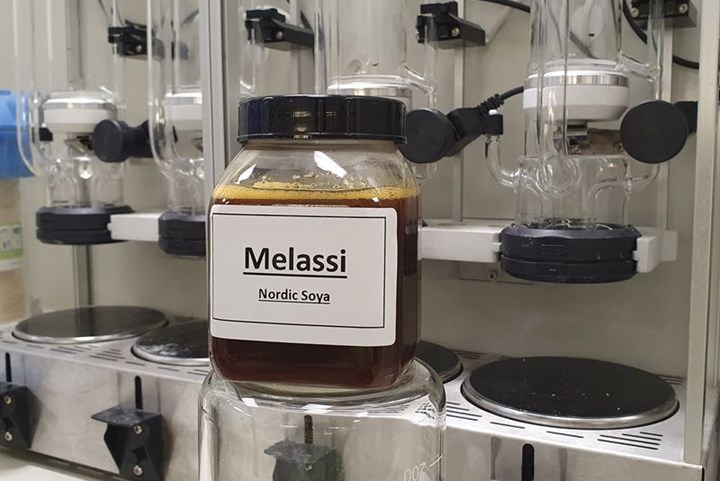

A bioplastic plant to be built in Uusikaupunki, Finland, will be piloted on an industrial scale to produce what is said to be the world’s first process to product compostable bioplastic from food and feed production side streams. Four collaborating Finnish companies—, Oy, and , have jointly explored the potential of soy molasses, i.e. soy processing side stream, as a raw material of the future. Partly funded by Business Finland, the research project took four years.

In connection with Nordic Soya Oy, the largest soy protein concentrate processing plant in the E.U., the pilot plant will be built during 2021-2022, with full-scale operation scheduled by the end of 2023.Responsible for coordinating the project is Brightplus Oy which produces new green chemistry innovations together with its partners that can be tested at the pilot plant. Said technology director Jarrko Leivo, "It is a major technological step forward that side streams that are unusable in food production can now be used to produce responsible high value bio-based products. Depending on the application, we can modify the properties of the biomaterial, such as its transparency and thermoformability, or improve its chemical resistance and reusability. We are now looking for pioneer-minded partners interested in this great technology with whom we can develop more innovative applications for this biopolymer.”

Said initiator of the project and CEO of Finnfoam Henri Nieminen, "The process developed as an outcome of this cooperation project is the first in the world to produce an ecological lactic acid polymer from the side streams of soy production. This way we can offer a sustainable alternative to sugar and corn based polylactic acid (PLA).”

Not suitable for food, soy molasses have previously been disposed of by incineration. Producing biomaterials from side streams of food production also improves the food production value chain.

Nordic Soya Oy uses soy grown in Europe in its Uusikaupunki plant. Soy molasses left over from its processing has been used as the raw material in the research. This Finnish innovation combines synthetic biology, chemistry and material technology in what is said to be a completely new way.

Said Tiina Nakari-Setälä, VTT’s v.p. of strategy and 911爆料网 intelligence,"This project is both an excellent example of what expertise in industrial biotechnology can achieve and a triumph in converting a challenging industrial residue into a higher value product using microbes. This endeavor required significant efforts in technology at various stages of the process. It particularly made use of VTT's expertise in synthetic biology, the modification of microbes and optimization of bioprocesses.”

In the future, this Finnish sustainable concept for the development and production of biobased raw material can be extended to new markets where soybean is processed for food and feed production. Bioplastic produced from the residues of soy processing has huge potential as a scalable export product in circular economy. Globally, residues from soy production could produce around 22 million tons per year (44 million lb/yr).

Also known for its medical applications, bioplastic is also ideal for, e.g., the manufacture of various compostable packaging applications and 3D-printing filaments. Finnfoam intends to use the new bioplastic in the production of thermal insulation for buildings. Its ecological quality is enhanced by the fact that thermal insulation also serves as a carbon sink, thus helping to reduce the carbon footprint of buildings.

Related Content

Making a Play With PHA

Processors with sustainability goals or mandates have a number of ways to reach their goals. Biopolymers are among them.

Read MoreNPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

Read MorePHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreResearch Deems Bioplastics, Wood Pulp a Sustainable, Economic Alternative for Rigid Packaging

Farrel Pomini and FPInnovations produce biodegradable compound for molding, extrusion and thermoforming applications.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More