Molding Straighter Medical Tubes: New Hot-Runner Technology Battles Core Shift

A curvature or bowing effect in thin-wall PET blood tubes had long been accepted as the norm for the high-volume application, despite its impact on cycle time and downstream post-molding operations.

The flow ratio (L/t) of blood tubes, which requires resin to travel a great distance relative to the tubes’ thin wall, makes the application inherently challenging. That difficulty is further exacerbated by the slender cores used to form the inside of the tubes, which are slight enough to be shifted by the melt upon injection.

To overcome this movement, molders often add hold time and hold pressure to the process to correct for any shift, lengthening the cycle. Despite these efforts, the tubes often maintain a bow, which might be imperceptible to the human eye but whose non-concentricity affects downstream operations, including labeling machines.

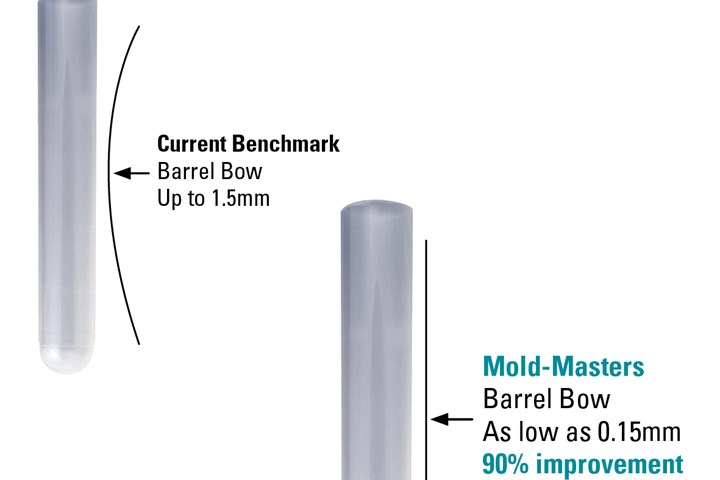

The seeming insurmountability of these hurdles led molders and their customers to accept a barrel bow or “banana” curve of 0.5 to 1.5 mm in the end product. Seeing a possibility to apply technology to improve the outcome, Mold-Masters set out to mold a better barrel and succeeded, cutting barrel bow to as little as 0.15 mm—a 70% to 90% reduction.

In addition to lightweighting the tube, reducing cycle time, and lowering scrap, the molding advance created tubes that rolled concentrically in the labeler, increased final-stage throughput and minimized machine downtime, according to Mold-Masters.

Symmetrical Fill

Thomas Bechtel, global sales director for packaging and medical at Mold-Masters, tells Plastics Technology that despite industry acceptance of bowing, his company perceived an opportunity for progress. “We saw a chance to help customers achieve better cycle times, so they’re not limited by core shift,” Bechtel noted, adding that in downstream processes, the parts are easier to process if they’re flat.

Bechtel says that all hot-runner valve-gate systems are affected by how and where the melt stream strikes the nozzle’s pin. Using the analogy of a tree and the sun for the pin and the melt, Bechtel describes how there will always be shade opposite the sun on one side of the tree. “This applies to the valve pin and melt,” Bechtel says; “there is always a ‘shadow’ on the opposite side of where melt entered.”

To overcome core shift or bending from the uneven distribution of melt, molders normally apply greater hold time and hold pressure to “push things back where they should be,” Bechtel explains. “Now they run a process that’s

Mold-Masters saw improvement of as much as 90% in barrel bow for blood tubes utilizing its new technology.

optimized for cycle time, not hold time.”

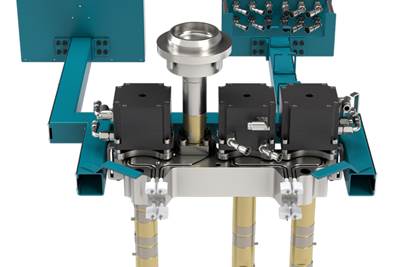

Mold-Masters’ patent-pending solution is to feed gates from multiple sides of the part, creating multiple “valve-pin shadows” that equalize each other. Mold-Masters’ Richard Gane says this creates symmetrical cavity fill instead of the normal process where the melt follows the path of least resistance, causing core shift. In taking that path, Gane says, the bow is baked into the tube. As the core moves, the barrel wall can become thicker or thinner on one side, leading to disparate shrink rates in the final part, and, ultimately, distortion.

“By minimizing core shift,” Gane says, “we’re minimizing the barrel bow, the banana effect.” Gane says cycle-time savings vary by application, with some tubes produced in 96-cavity tools, but reductions of up to 2 sec are possible.

Related Content

New Hot Runner Temperature Control

Oerlikon HRSflow’s T-Flow HRS control has launched with three models that are configurable to multiples of six zones.

Read MoreEnd Ring Valve Gate Optimizes Multicavity Application Injection Molding

The EYEgate HRS features a specially designed pin guide system engineered to ensure permanent pin-gate alignment to significantly enhance the end ring’s durability.

Read MorePET Preform Hot Runner System Reduces Stack Height

Mold-Masters has cut the stack height of its PET-Series hot runner system from 300 mm to 260 mm, while maintaining a 3-plate design and the advantages therein.

Read MoreRFID Applied to Hot Runner Systems

Hasco says the adapted variant of the Mold Tag makes it possible to read out all data on the hot half or a wired system directly on a smartphone.

Read MoreRead Next

Valve Gate Hot Runner Integrates New Servo Motor

The compact direct-drive servo motor design minimizes stack height and simplifies mold design.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More