Packaging: New System Produces Wide Variety of ‘Tethered’ Bottle Caps.

A wide variety of tethered caps, designed to meet EU regulations for 2024, can be produced on a new compact, high-speed line from SACMI.

Italian packaging machinery producer SACMI has responded to new European Union requirements with a versatile line of machinery for producing “tethered” bottle caps. EU Directive 2019/904, issued in June 2019, requires that in 2024, caps on single-use beverage bottles will remain attached, or “tethered,” to the bottle, as a means of preventing the caps’ dispersal in the environment, thus thwarting efforts at recycling.

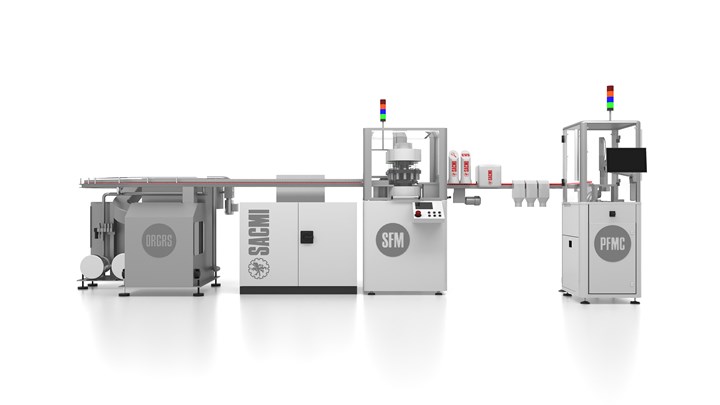

A wide variety of tethered cap designs—either compression or injection molded—can be handled by SACMI’s new system.

SACMI’s new line consists of four modules for feeding, scoring, folding and inspecting both tethered and traditional caps. While traditional caps have horizontal-cut tamper-evident bands, SACMI’s system can produce at least eight types of tethered caps with hinges or single or dual tether strips, some with ability to “lock” the cap away from the bottle neck for ease of drinking. All these types of caps could be molded either on SACMI’s popular continuous compression molding (CCM) machines or by injection molding.

The first module is the ORGRS (at left in the photo), described as sturdy and “extremely compact” waterfall feeder that orients and feeds the caps. Newly designed according to user feedback, it features faster maintenance and cleaning, thanks to easier internal access; many components can be disassembled without tools. It’s also said to run very quietly, due to soundproofing and low-noise compressed-air blowers. A deionizer is an available option.

Next in line is the SFM08 module, which scores and folds the tamper-evident band. This rotary star-wheel system can be equipped with 8 + 8 or 4 + 4 scoring and folding stations; it can handle caps from 18 to 55 mm diam. and 10 to 23 mm high. It boasts very fast cutting-tool changeover and easy access to all components. Like SACMI’s existing cutting machines, its spindles are rotated by dedicated servomotors, and it can be configured to fold and score or score and fold, according to the cap design. It can utilize many of the same spare parts as existing machines.

Four main modules make up SACMI’s downstream line that can process up to 1000 caps/min, or twice that number with an upgraded scoring/folding module.

Caps leave the SFM module on a fast-moving narrow belt, which carries them past CVS video inspection devices and air-jet nozzles to expel rejects and samples for testing by the pull-force measuring machine at the end of the line (see below). The CVS154 and CVS 360-3D multi-camera devices inspect the cap body, interior and sidewall for key dimensions, structural defects, color variation or contamination (black specks). It can also recognize the cavity number to maintain quality statics by mold cavity.

Finally, the PFMC unit inspects the cut of the tamper-evident band and measures its breaking force. This unit performs destructive tests on selected cap samples. It can work as a standalone unit or integrated in a production line. It can also test traditional tamper-evident caps. This unit integrates a CVS CUT camera device to inspect the tamper-evident band before the destructive test, and it records quality statistics associated with individual spindles of the SFM module. Quick format changeovers allow testing of caps of different diameters. It also provides feedback control of cutting-tool temperature to counteract any drift in cutting performance.

The compact line is designed for up to 1000 caps/min (60,000/hr), though it can be modified for up to twice that output with a 12-station folding/scoring module.

Related Content

Using Data to Pinpoint Cosmetic Defect Causes in Injection Molded Parts

Taking a step back and identifying the root cause of a cosmetic flaw can help molders focus on what corrective actions need to be taken.

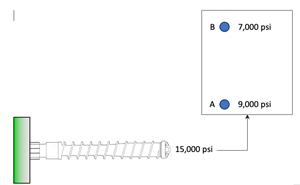

Read MoreUnderstanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreUse These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.

Read MoreRead Next

K 2019 Report: More Control, Faster Ordering for Molds, Hot Runners

Online monitoring of existing systems and configuration and ordering of new molds were featured at K 2019, as were numerous advances in valve-gate controls.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More