best practices

Best Practices in Processing with Recycled Material

Inside: What brand owners are planning, and how processors ahead of the curve have already responded.

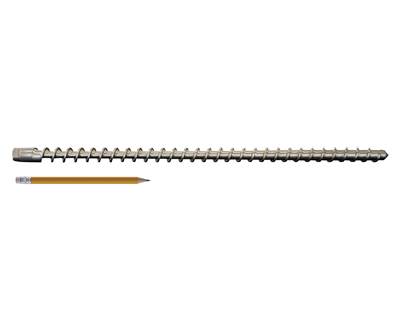

Read MoreWhat You Should Know About Miniature Extrusion Screws

Very small screws have become more common with the growth of additive manufacturing. Designing such screws requires balancing their output requirements with their torque strength.

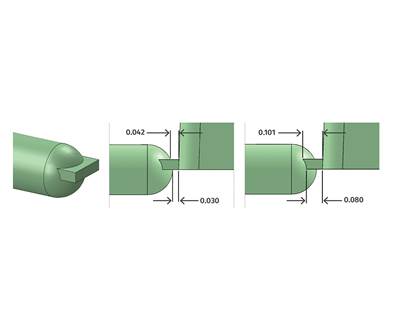

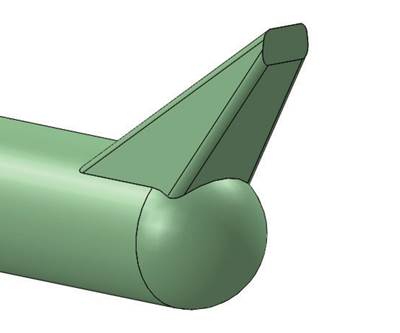

Read MoreTooling: How to Properly Size, Gates, Runners and Sprues, Part 3

Get the sprue, runner and gate sizes close to ideal the first time around.

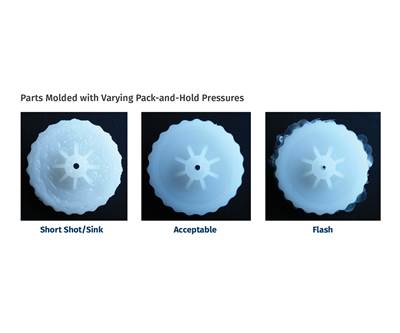

Read MoreThe Cosmetic Process Window: Key to a No-Tweak, Robust Process

Establishing a process with the widest possible cosmetic window can help put your injection molding on cruise control.

Read MoreTooling: How to Properly Size, Gates, Runners and Sprues, Part 2

Get the sprue, runner and gate sizes close to ideal the first time around.

Read MoreCompounding: Part 2 of 2 Demystifying Devolatilization

Here are some simple tools to help monitor and optimize your devolatilization process.

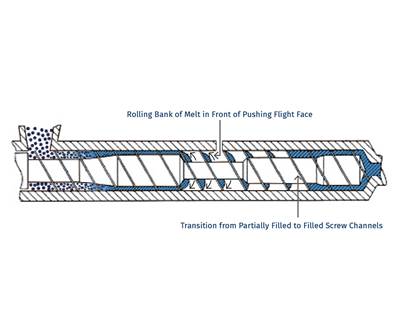

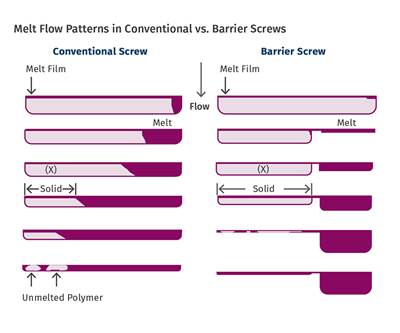

Read MoreExtrusion: Important Polymer Melting Equations for Extrusion Processors

The more you know about what happens in a screw, the more you’ll be able to work with your supplier to optimize design.

Read MoreAward-Winning Package Boosts Lindar's Thermoforming Credentials

Custom thermoformer Lindar has experienced years of steady growth, with numerous technical advances to its credit, as it continues to expand its capabilities in packaging and industrial markets.

Read MoreBe Proactive in Your Purging Program

True, it can be tough to take a machine out of production, but a purging maintenance program should be thought of as a direct line to cost savings.

Read MoreMaterials Part 1: What Annealing Can Do for Your Process

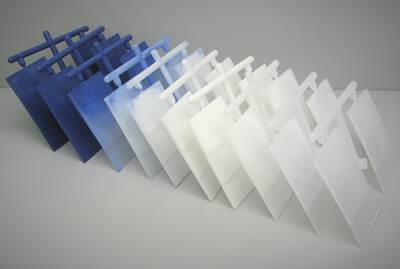

Relatively rapid cooling rates in processing introduce internal stress. If functional problems in use result, annealing may draw down the stress to levels that may not be achievable during processing.

Read More