best practices

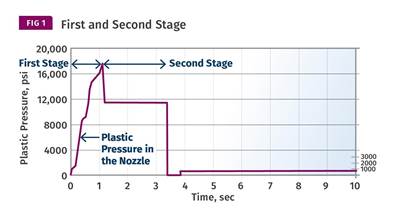

Injection Molding: Fill Based on Volume, Not Weight

Most parts should be 90-99% full after first-stage—by volume not weight. Here’s why that’s important and how to make a first-stage-only part.

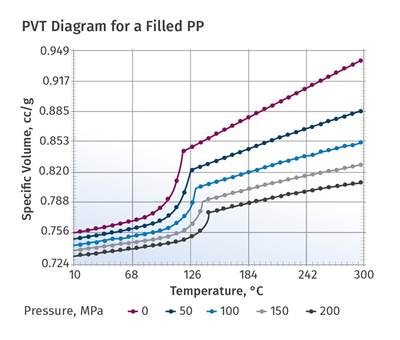

Read MoreA Processor's Most Important Job, Part 7: Reviewing Crystallinity

There are several process-related issues that influence crystallinity besides cooling rate. Let’s examine a few.

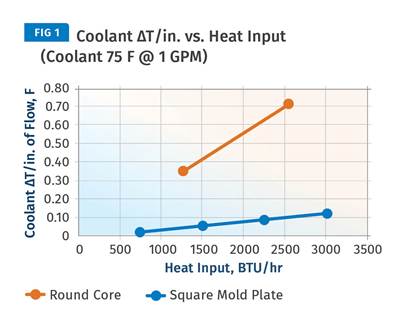

Read MoreAn Engineering Approach to Mold-Cooling Circuit Design

The Energy Density vs. ΔT/in. relationship is an important step forward in pursuit of a science-based approach to cooling-circuit design. Here’s why.

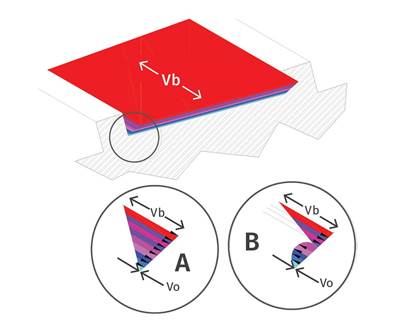

Read MoreExtrusion: A Simple Way to Evaluate Your Screw Performance, Part 2

A hand-held calculator and some basic equations can help determine whether your screw is up to snuff.

Read MoreIndustry 4.0 Gives DMT a Sharper Edge

Leading maker of blade sharpeners boosts productivity in captive molding with cutting-edge connectivity.

Read MoreInjection Molding: Safety First—Know the Compatibility of Different Resins

Certain materials don’t play well together when mixed. So it’s best not to. Here are some guidelines.

Read More‘Intelligent’ Cooling Helps Molder Improve Productivity, Profitability & Quality

Cost-effective and user-friendly process-cooling system gives custom molder the ability to do more with less.

Read MoreInline Inkjet Printer Keeps Pace With Speedy Wire & Cable Processor

Huber+Suhner is outfitting its six high-speed extrusion lines with new high-speed, continuous inkjet printers.

Read MoreRapid Heat & Cool Molding Evolves to Meet Industry Challenges

Technical capabilities of the process have advanced to erase former cycle-time penalties, and ongoing developments address creation of a materials database and new applications in hybrid composite injection overmolding.

Read MoreThe One Company Solution

Primex has vertically integrated its color compounding, sheet extrusion, and fabrication 911爆料网es to provide a single-source solution to customers in a wide range of industries.

Read More