best practices

The Mystery of Physical Aging, Part 1: Knowing the Difference

In polymers, aging is commonly considered essentially synonymous with oxidation. But there are important differences between this type of chemical aging and less commonly recognized physical aging. Let’s unlock the mystery.

Read MoreUnderstanding the Effects of Paint On Plastics

Paint can have significant effects on mechanical properties of plastic parts. As illustrated by this OEM’s procedure in developing new-generation outboard-motor covers, there’s no substitute for thorough testing.

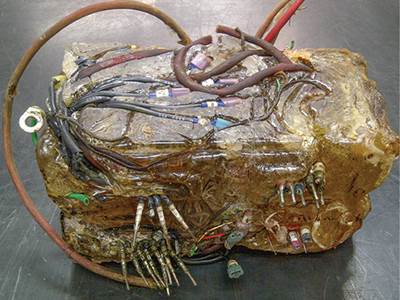

Read MorePrevent & Minimize Downtime in Hot Runner Molding

There are simple explanations for the most common hot-runner problems and equally simple ways to prevent them. One is to take advantage of features often overlooked in today’s hot-runner controls.

Read MoreThe Paradox of Proportioning

Continuous proportioning typically involves a group of gravimetric feeders operating under some form of higher level coordinating control. One would think the result should be a perfectly formulated composite stream. But the devil is in the details.

Read MoreAutomation Eliminates Contamination

Many molders use robots to boost output and repeatability, but SSI also uses them to prevent contamination of critical diagnostic products.

Read MoreRogan Corp. at 80: Growing in Medical, LSR, Two-Shot Molding

Bondable TPEs and LSRs support growth in two-shot molding for medical and other markets.

Read MoreFamily-Owned Thermoformer Continues to Flourish

By adding technology, home-grown tooling, and automation, industrial thermoformer C&K Plastics has grown while getting its costs under control.

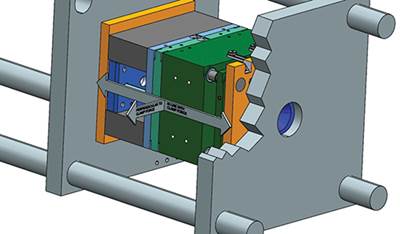

Read MoreTOOLING: Flash-Free Molding: Part 1

A robust process window relies a lot on tooling. So it stands to reason that making a tool change to address issues provides a more robust solution

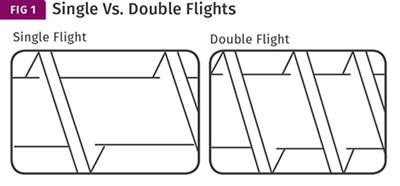

Read MoreEXTRUSION: Double Flights Are Not a Cure-All

There are certain applications where double-flighted feed sections make sense, and others where they don’t.

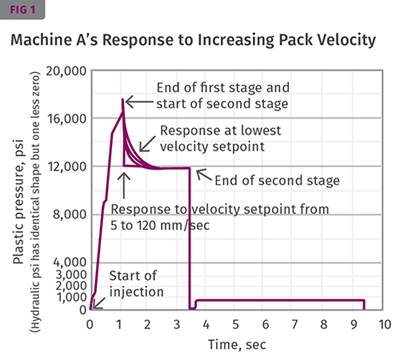

Read MoreINJECTION MOLDING: How Does Your Machine Control Pack Velocity?

You’ll need to find out in order to develop a molding process that you can repeat from machine to machine and mold to mold.

Read More