Blow Molding

Foam Blow Molding Advances to Commercial Use

W. Muller’s three-layer coextrusion head, with nitrogen gas injected in the center layer, has found its first commercial application in large agro-chemical containers.

Read MoreVersatile Stretch-Blow Molder for Wide or Narrow Necks

FlexBlow reheat stretch-blow molder makes bottles with 18-to-110-mm necks and supports quick changeovers.

Read MoreU.S.-Built All-Electric Shuttle from Bekum

Bekum’s EBlow 407DL targets high-speed production of small bottles.

Read MoreLarge All-Electric Shuttle Blow Molder

Hesta’s newest and largest machine has 900-mm mold stroke.

Read MoreEnhanced PET Stretch-Blow Technologies from KHS

KHS enhanced its Blowmax rotary reheat stretch-blow machine to meet demand for single-serve beverage bottles. It also developed what’s said to be the lightest half-liter PET bottle for still water.

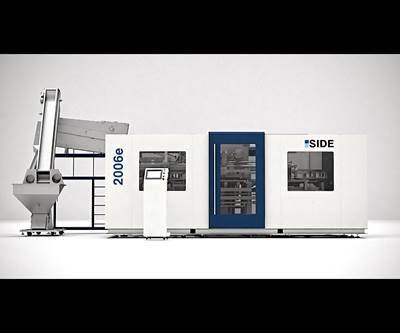

Read MoreNew PET Machines & Pinch-Handle Technology

SIDE presents a new generation of PET stretch-blow molding machines for products from 250 ml to 10 L.

Read MoreOne- and Two-Stage PET Machines for Higher Productivity & Specialty Products

Five machines from Nissei ASB are stretch-blow molding: beer bottles, airline liquor miniatures, sports bottles, premium cosmetics bottles, and wide-mouth, hot-fill jars.

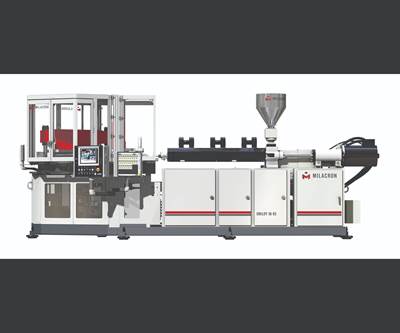

Read MoreInjection-Blow Machines with Energy-Saving Servo-Hydraulics

Jomar’s IntelliDrive servo-hydraulic pump brings major energy savings to injection-blow molding.

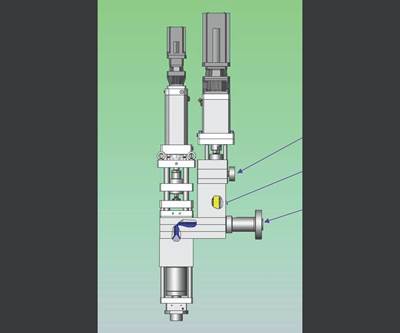

Read MoreInjection-Blow Molding Multi-Layer Barrier Bottles

Kortec hot-runner technology and an auxiliary injector convert a standard machine to three-layer co-injection blow molding.

Read More‘Mini’ Accumulator-Head Machine Comes to NPE

Small industrial blow molder with rapid color and material change.

Read More