Extrusion

Moving Die Parts Change Profile Shapes 'On the Fly'

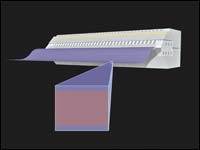

Change one tubing lumen into two, or two lumens into three, or even split one tube into two in a “Y” shape: These are some of the dramatic alterations that can be made “on the fly” with a novel articulated die concept available for license from Specialty Silicone Fabricators, a medical tubing maker in Paso Robles, Calif.

Read MoreSlip Agents: Extended Performance Range for Polyolefin Films

Newer specialty slip masterbatches go beyond traditional capabilities to provide greater thermal stability, reliability, and ability to hold COF steady during laminating.

Read MoreMicrolayer Films: New Uses for Hundreds of Layers

Early microlayer films gave an iridescent shimmer to decorative packaging. The newest films with hundreds and even thousands of layers are designed for gas barrier, uv blocking, electronic displays, and high-strength window-glass laminates. As applications grow, more processors want in on the action.

Read MoreFixing the Mixing in Wood-Plastic Profiles

Color consistency and durability are critical to wood-plastic composites, especially in outdoor applications.

Read MoreA Relic of Plastics’ Rough and Ready Days

In 1955, Allied Resins and Allied Resinous Products were prosperous, creative compounding and extrusion operations, respectively, situated across the street from each other in Conneaut, Ohio.

Read MoreNine-Layer Blown Film: Why It's a Challenge, What It Takes to Succeed

Eight years after nine-layer blown films were first introduced, only a handful of processors have mastered the challenges of making them. Machine suppliers are now setting up lab lines that could make entry easier.

Read More50 Ideas That Changed Plastics

Very few readers of this issue can remember, or even imagine, what it was like when an injection molding machine did not have a screw, but only a smooth-bore plunger.

Read MoreA Plant Designed by Efficiency Experts

Hi-Tech Profiles Inc. in Pawcatuck, Conn., extrudes stock and custom medical and industrial profiles out of engineering resins that cost from $3 up to $35/lb.

Read MoreFix Thickness Variations in Extruded Sheet

Non-uniform thickness in extruded sheet is a serious problem.

Read More'Corrugator Vacuum Forming'

Molding separate hollow parts on a pipe corrugator is a home-grown technique used by a small number of processors. They discovered it offers higher outputs and numerous other advantages over blow molding for making tube-shaped, precision medical, automotive, and appliance parts. But the process has not yet realized what could be its greatest potential in closed-end parts like bottles.

Read More