Injection Molding

Pellet to Gate Control: The Value of a Holistic View of Melt Management

Molders tend to think about the elements of a melt-delivery system, from screw to hot-runner gate, in isolation from each other. But taking an integrated view of the whole system can have big consequences for cycle time, part quality, scrap rates, and energy consumption.

Read MoreVFD or Servo Drive for Energy-Saving Hydraulics? Why Not Both?

New VFD from Bosch Rexroth at NPE2018 illustrates the merits of VFD versus servo drive for hydraulic pumps.

Read MoreSomething for Everyone at Wittmann Battenfeld’s 10th Anniversary Celebration

New injection machines, robots and auxiliaries; plus additional steps toward Industry 4.0 were on display at Wittmann Battenfeld event.

Read MoreTechnology Showcase at Wittmann Battenfeld’s 10th Anniversary Event

New injection machines, robots, auxiliaries, and software highlighted the two-day gala, along with some peeks at the future of “smart factories.”

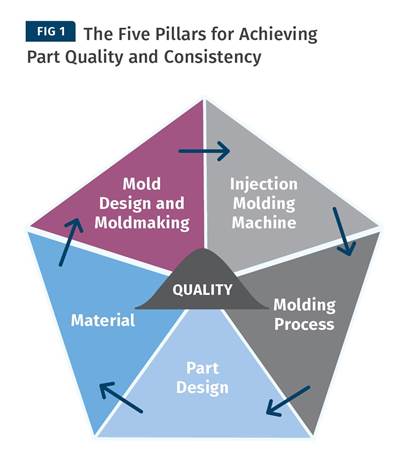

Read MoreImproving Molding Process Capability: The Role of the Five Essential Pillars, Part 2

Each contributes to molded-part quality, and each must be optimized before production begins.

Read MoreGet Free Guidance on Molding Resins

Mobile Specs app and website provide processing parameters on thousands of resins … at no cost.

Read MoreNew Webinar: How to Use Simulation to Reduce Material and Part Cost

Register for this free webinar on reducing downstream risk through injection molding simulation software. (Sponsored Content)

Read MoreIn Food Packaging, Peelable IML Serves as Tamper-Evident Seal

Eliminate threaded closures and induction-sealed liners with ‘functional’ IML.

Read MoreNegri Bossi Puts a New Spin on Microcellular Foam Molding

Negri Bossi’s FMC technology injects nitrogen gas through the center of the screw to foam LSR or thermoplastics—or both at the same time.

Read MoreWittmann Battenfeld Celebrates 10th Anniversary with Launch of New Machines

Celebrating 10 years since the acquisition of the Battenfeld brand with new vertical presses, all-electric machines for high-speed packaging, and additional large-press sizes.

Read More