Injection Molding

Conformal Cooling Product Lines for Injection Molding and Blow Molding

Conformal cooling is a design approach for improving mold and die productivity that can save 10-50 percent or more on cycle time, in addition to quality benefits and improved tooling durability.

Read MoreThe 3-to-7-Minute Color Change—Step 3: Color Planning

It is important to understand what to expect when changing from one color to another; here’s a method to analyze what steps must be taken from a cleaning standpoint.

Read MoreNAI Reshores Some Connector Molding

After closing U.S. manufacturing in 2009 following the telecom and broader market collapse, NAI is opening a new production site in Michigan, including injection molding.

Read MoreThe 3-to-7-Minute Color Change—Step 2: Preparation & Equipment

Hopper and screw and barrel considerations come into play as do strategies: press-side loading, satellite hoppers or a combination of both?

Read MoreHigh-Speed Packaging & Medical Demos from Netstal

Injection molding technologies for packaging and medical molding are on display, with an emphasis on Industry 4.0 functionality.

Read MoreNew Servo-Hydraulic Toggles & Two-Platens from FCS

High-precision, high-speed molding with reduced energy consumption.

Read MoreKraussMaffei’s Integrated Molding Cells Focus on Five Technologies

High-speed machines, LSR, composites overmolding, Industry 4.0 and more showcased.

Read MoreNew Servo-Hydraulic Toggles for Two-Shot Molding

New two-component press with rotary table and multiple injection-unit layout options.

Read MoreVideo: Workforce Development Panel at Molding 2018

A panel discussion during Molding 2018 centered on ways the plastics industry can collaborate and coordinate on bringing talented new people into its workforce.

Read MoreA New Way to Mold Better Parts Faster and Easier

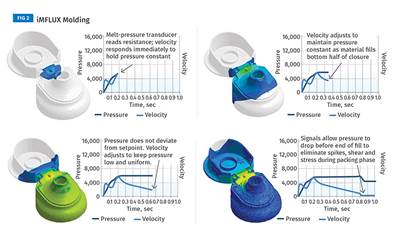

A new injection molding process ‘breaks all the rules’ by using low, constant pressure to achieve faster cycles and better-quality parts.

Read More