Injection Molding

Tooling: Hot Sprues—Mold a Disk or Not?

Having a hot sprue shut off against the parting line versus intentionally molding a thin disk has been the subject of controversy for many years.

Read MoreFully Automated Mold-Change Is Here

An integrated solution using Stäubli's technology in a smart-factory setting shows how Single Minute Exchange of Die can work.

Read MoreCold Pressed-In Threaded Inserts: An Economical Alternative

Cold pressed-in threaded inserts provide a sturdy and cost-effective alternative to heat staking or ultrasonically installed threaded inserts. Discover the advantages and see it in action here. (Sponsored Content)

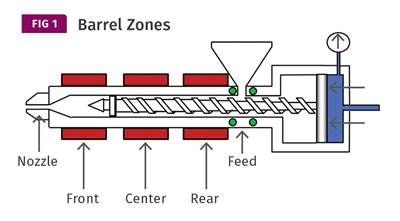

Read MoreInjection Molding: How to Set Barrel Zone Temps

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreReally Big Machines Dominate Milacron Booth

The largest machine at this NPE—or any NPE to date—is Milacron’s new 2250-ton Cincinnati machine. Not to mention the massive platen of a 6600-tonner now under construction, also on view.

Read MoreAutomotive Composites With a Soft Touch

Auto interior component marries continuous-fiber composite with hard/soft overmolding.

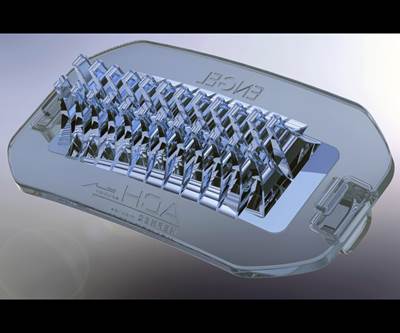

Read MoreLSR Headlamp Lens Uses Auto Cavity Balancing

Engel molds complex LSR automotive headlamp lenses with the help of a new valve-gate cold-runner system.

Read MoreAutomatically Set, Maintain Ideal Cooling Parameters for Temperature Control Units

Engel will use NPE2018 as the North American launch of its iQ flow control software.

Read MoreAugmented Reality In Reality

As I approached the booth, my worst fears were confirmed. I’d have to put on the virtual reality goggles, wouldn’t I?

Read MoreQuick Changeover: The 3-to-7-Minute Color Change

Step 1: Assessment—These questions must be asked during the development of fast changeover procedures.

Read More