Injection Molding

‘Organic Hybrid’ Composites Highlighted at K Show

One of the materials trends hailed at this month’s K 2010 show in Dusseldorf was the replacement of plastic-metal “hybrid” composites with all-plastic “organic hybrids” in structural parts for automotive and other markets.

Read MoreInjection Molding: Processors: Teach Part Designers The Golden Rule

Make sure the designers you work with understand that there are limits to what processing can do.

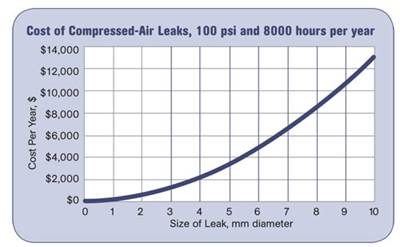

Read MoreEnergy Miser: Plug Costly Compressed-Air Leaks

Last month we introduced the idea that compressed-air usage is one of the first places any manufacturer should look to reduce energy cost.

Read MorePMC Proves It’s Not Too Late To Pioneer in Medical Molding

Molding medical devices is a high-end 911爆料网 that has proven more resistant to economic swings and to foreign competition than some other plastics markets.

Read MoreTooling: Setting Up Shop—Part II of III

Many repair shops in molding facilities are too small, poorly lit, and inefficiently designed.

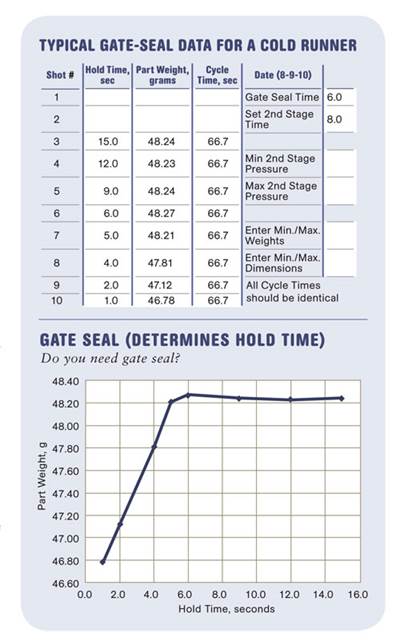

Read MoreInjection Molding: Why & How to Do Gate-Seal Experiments

Part of optimizing any molding process is determining the second-stage injection, or pack and hold, parameters.

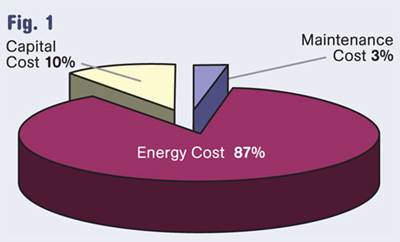

Read MoreCompressed Air Isn’t Free!

Compressed air is a convenient and often essential utility, but it is very expensive to produce, and most of the energy used to compress air is turned into heat and then lost to the system and environment.

Read MoreK 2010 Preview, Auxiliaries: Equipment of All Types Debuts This Month at K 2010

From materials drying, feeding, and blending to process heating/cooling, scrap reclaiming, testing, welding, and decorating—the K 2010 show this month in Dusseldorf, Germany, will have news in all categories of auxiliary equipment.

Read MoreTips and Techniques: How to Get Best Results With Insert Fasteners

The weakest sections of many plastic part designs are the joints and assembly points.

Read More