Injection Molding

Taking the Temperature of Mold Productivity

Increasing traffic in transfer tooling from molders that have shuttered operations or are unable to successfully produce parts is driving interest in a long-established but under-utilized diagnostic technique for injection molding.

Read MorePay Attention to Your Nozzle Body & Tip

These are overlooked components that can cost you thousands.

Read MoreFoamed PET Bottles for Beer

Now the foam isn’t just on top of the beer, it’s all around it.

Read MoreTOOLING: Standard Components and In-Mold Monitor at K 2010

K 2010 news in tooling aims at helping injection moldmakers speed product to market.

Read MoreTips and Techniques: How MedPlast Became a Multi-Shot Specialist

It started in a garage and evolved into a multi-plant, $100 million operation that holds particular expertise in multi-shot molding.

Read MoreTips and Techniques: How to Mold & Extrude Using Chemical Foaming Agents

Here are some tips and techniques for extruders and injection molders to refer to when using CFAs.

Read MoreInjection Molding: How to Set Second-Stage (Pack & Hold) Pressure

Most molders work with two parameters for establishing second-stage pressure. But within Scientific Molding there are actually four.

Read MoreTroubleshooting: Injection Molding Seven Steps Toward Scientific Troubleshooting

A scientific troubleshooter is not someone who pushes buttons faster or has more tricks up his or her sleeve.

Read MoreCalcium Buildup Causing Mold-Cooling Headaches

There are some amazing technologies to prevent calcium scale buildup for injection molders that are relatively inexpensive.

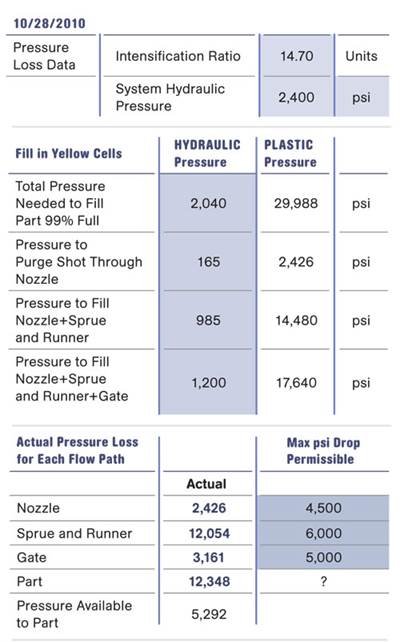

Read MoreInjection Molding: Understanding Pressure Loss In Injection Molding

One of the more prominent trends in processing is the need for higher plastic pressures to mold parts.

Read More