Injection Molding

Central or Portable? ‘Off-the-Floor’ Central Chillers Cost Less, Provide Processing Gains

In deciding whether to use portable or central chillers, there are a variety of variables to consider. Here are the key issues.

Read MoreCentral or Portable? Flexibility Favors ‘Discrete’ Chillers

Why might discrete chillers be a solution in your plant? In a word: Flexibility. Here is the lowdown.

Read MoreWhy & How to Assemble Parts While They’re Still Warm

For any molder seeking to maximize productivity and efficiency, carefully managing inventory and warehouse space is a key concern. One way to address this challenge is to assemble parts directly out of the mold, when they’re still warm.

Read MoreCalculate Shot Size Vs. Barrel Capacity

It may seem like a dull topic, but it will overcome the emotional experience that follows when you put a new mold into a machine and you find out there is not enough barrel capacity to make a full shot.

Read MoreMold Maintenance Training Eases Molder's Growing Pains

Automation Plastics in Aurora, Ohio (automationplastics.com), is a 32-year-old custom injection molder with 50,500 ft² and 30 presses from 35 to 700 tons.

Read MoreExtrusion & Injection Molding in One Automated Process

A large German manufacturer of hoses, cable ducts, and other extruded automotive components recently expanded its activities into the white-goods appliance sector.

Read MoreLSR Part III-- Choosing a Mixing/Metering System

Liquid silicone rubber (LSR ) is a two component reactive chemical with a viscous, paste-like consistency.

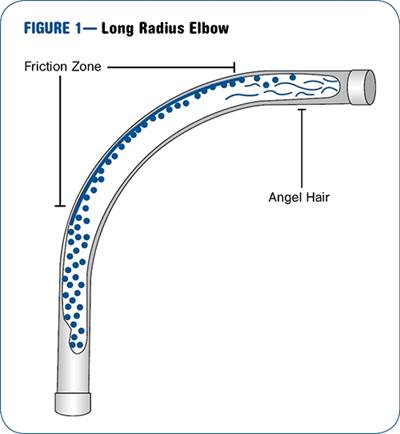

Read MoreAvoid Those Devilish ‘Angel Hairs’

Angel hairs wreak havoc on plastics processing: clogging filters, plugging conveying lines, causing feed problems at the blender, and jamming up machine throats. Here's how to prevent their formation.

Read MoreVision Inspection Integrated with Press Control

Machine-operator access to 100% quality inspection of micro-part dimensions is available with the new PowerVision option from Wittmann Battenfeld, Torrington, Conn.

Read MoreTool Room Management: How To Lead Your Team

Real progress in a mold shop won’t be made without a qualified and motivated “driver at the wheel” who diligently searches for, and implements, continuous-improvement solutions.

Read More