Injection Molding

UV Cure Solves LSR Processing Challenges

Extended cure times for thick parts and temperature sensitivity of pharmaceutical additives are two challenges for silicone molding and extrusion that can be overcome with new low-temperature UV curing technology.

Read MoreMolder Slashes Energy Cost With Move to Desiccant Drying

Yes there are still molders drying with tray ovens. But this processor replaced the last few it had and has reaped some impressive energy-savings benefits.

Read MoreGetting Good Data from DOE

How do you know what process variables control a part鈥檚 dimensions or other properties? A properly conducted DOE is the answer鈥攂ut incorrect procedure will yield useless data.

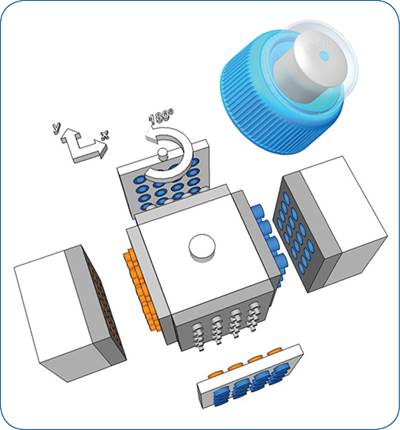

Read MoreTooling at NPE: A Hot-Runner Bonanza in Orlando

Most of the emphasis is on valve gating and on doing more in less space. Other highlights include standardized mold components, some impressive feats of moldmaking creativity, and advances in mold simulation.

Read MoreInjection Molding: Speed, Automation & Integration

Hot buttons at the show will be multi-component molding, in-mold labeling/decorating (IML/IMD), in-mold assembly, medical molding, liquid silicone rubber (LSR), micro-molding, and high-speed packaging.

Read MoreLiquid Infusion of UV Stabilizer

Process involves dipping the parts in an aqueous bath for a short period

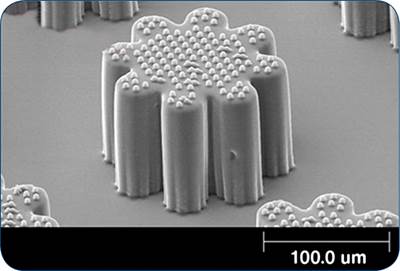

Read MoreSecrets of Success in Micro Molding

Medical-device, electronics, and biopharmaceutical manufacturers need new micro-molded products to create tinier, less invasive, and/or space-saving micro devices.

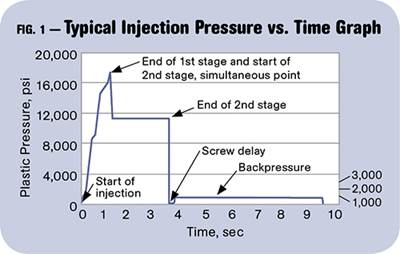

Read MoreImprove Profits by Graphing Injection Pressure

Graphing is a powerful aid in optimizing the process and troubleshooting both process and machine issues.

Read MoreNow You Can Measure Pellet Moisture In the Hopper, in Real Time

Take the guesswork out of drying with new technology.

Read More