Injection Molding

Molder Takes 3D Printing In-House to Speed Product Development

“Bringing this function in-house is very much in keeping with the way our company conducts its 911±¬ÁĎÍř.

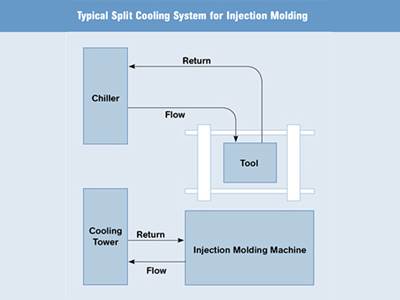

Read MoreEnergy Miser: For Energy-Efficient Water Cooling, Raise Temperatures to Cut Demand

Many plants use chilled-water temperatures that are far lower than are actually needed by the process. This has a direct effect on the cost of chilled water.

Read MoreNew Machines & Processes for Medical, Auto, Packaging, Electronics

Engel’s technical symposium in June attracted 2700 visitors from 35 countries to two days of technical presentations and 18 injection molding exhibits at the company’s plant in St.

Read MoreEstablish a True ‘24/7’ Production Process

New or existing mold trials need to produce a production-worthy process that will run 24/7.

Read MoreUnderstanding Automation for Pipette Molding

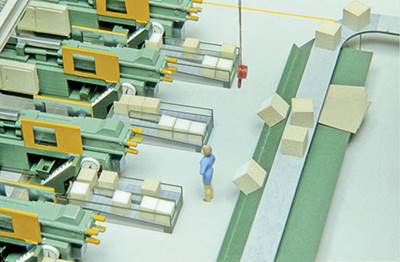

While simple looking enough, the pipette can be challenging to process. They generally have to be produced in high volumes without sacrificing quality due to their demanding applications. Automation is key to making this happen.

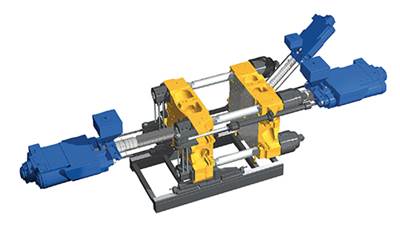

Read MoreAutomotive Molders Add Big Multi-Material Presses

Two companies of the Automotive Components Div. of The Windsor Mold Group, Windsor, Ont., recently commissioned several 2200-ton multi-component injection machines from Engel Machinery Inc., York, Pa.

Read MoreNews in Injection Molding Control & Monitoring from NPE2012

There were also several interesting developments in injection molding control and monitoring systems at this past April’s NPE2012 exhibition in Orlando, Fla.

Read MoreNew Injection Screw Breaks the Rules, But Fixes Many Molding Defects

“Revolutionary” screw design turns conventional plastication theory upside down.

Read MoreOvercoming IML’s Challenges To Reap Its Rewards

In-mold labeling has advanced dramatically over the past 20 years, but mostly in Europe. Here is what you need to know to bring IML to your operation.

Read MoreDo You Still Get Stubborn Surface Defects, Even With Sequential Valve Gating?

Sequential valve gating either eliminates or greatly reduces the flow-front collisions, and resulting knit lines, between a set of nozzles. However, there are still applications using sequential molding where a “ghost mark” or marks occurs on the part between a set or pair of nozzles and/or near the gate itself.

Read More