Injection Molding

Molded Spool Specialist Sees Growth Opportunities in Extrusion

Spools, reels, and more spools鈥nd now custom profile extrusion has been added to the mix.

Read MoreHow to Specify A Resin Dryer

To dry your polymer correctly you need a dryer that is properly designed and working properly. Here are my suggested specifications, for a two-, three- or four-bed desiccant dryer, the most common types used.

Read MoreKraussMaffei Group Sold to Investors

In late September, Onex Corp., a Toronto-based private-equity firm, agreed to acquire the KraussMaffei Group of Germany for around $735 million from Madison Capital, which had owned KraussMaffei since 2006.

Read MoreThe New Lightweights: Injection Molded 'Hybrid' Composites Spur Auto Innovation

A thermoplastic composite technology that emerged just a couple of years ago promises to make dramatic strides within the next two years in automotive mass production of structural components.

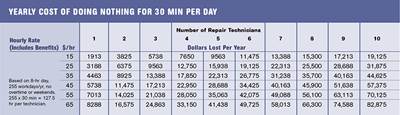

Read MoreUnderstanding Gravimetric Blender Accuracy & Payback

Accuracy is one of the least understood aspects of blending. The differences between batch and continuous blenders, how blend accuracy is calculated and controlled, which blender type is more accurate, how much accuracy is really required, and how payback is calculated are discussed here.

Read MoreTop 10 Reasons Why Molders Fail At Implementing ‘Scientific Molding

What is Scientific Molding? And why do molders seem to have such a difficult time embracing its concepts? Here are some thoughts on the matter.

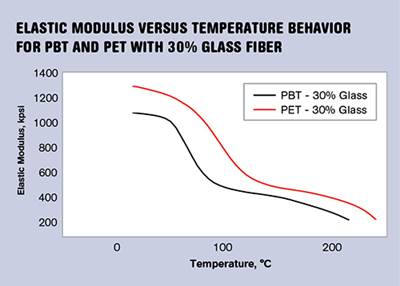

Read MorePBT & PET Polyester: Part 2 The Performance Factor

All things being equal, PET will outperform PBT mechanically and thermally. But the processor must dry the material properly and must understand the importance of mold temperature in achieving a degree of crystallinity that allows the natural advantages of the polymer to be realized.

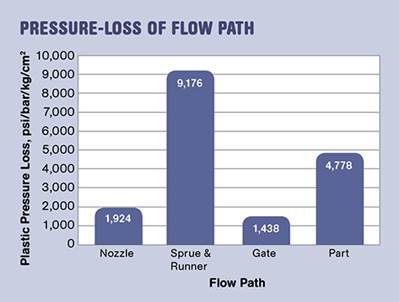

Read MoreGet the Most From Your Tooling

The history and culture of the molding industry has been to pull out every trick possible to work around design, resin, tooling, processing, and testing issues once the mold arrives. It is time to rewrite history.

Read MoreNovel Materials Stretch Process Capabilities

The potential for new or unusual materials to broaden the application potential of standard plastics processes was explored in a number of papers at April’s SPE ANTEC conference in Orlando, Fla.

Read More