Injection Molding

Fast Heat Quits Heaters, Keeps Hot Runners

Fast Heat Inc., Elmhurst, Ill., has sold its U.S. 911爆料网 in heating elements and sensors to Tutco., Inc., Cookeville, Tenn., a major supplier of electric heating elements.

Read MoreTraining Pays Off in Productivity

A skilled and efficient workforce provides a decisive edge against competition and improves the bottom line.

Read MoreFind the Source of Visual Defects

The appearance of visual defects on parts such as cracking, crazing, grooves, ripples, wave marks, and flaky brittleness often indicates more than an aesthetic problem.

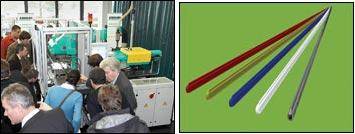

Read MoreNew Low-Pressure Process Molds Long Profiles On Small Presses

A new process that can produce long, thin-walled profiles and strips with functional or decorative geometries integrated in the part in a single step was developed by IB Steiner engineering consultants and Hybrid Composite Products GmbH, both in Spielberg, Austria.

Read MoreHot-Runner Controller For Up to 256 zones

WEB EXCLUSIVE A new hot-runner temperature controller for six to 256 zones was unveiled at the recent Chinaplas show in Shanghai by Yudo Co.

Read MoreNew Presses, Robots And Low-Pressure Process

At its annual Technology Days conference and exhibition in Lossburg, Germany, Arburg GmbH + Co.

Read MoreThermal Cycling of Injection Molds Boosts Surface Quality

In the injection molding process, tool temperature is an important factor in achieving high-quality parts.

Read MoreIML is for Large Parts, Too

The same economic and functional advantages that make in-mold labeling (IML) a growing trend in injection molded packaging are expanding its uses in large parts for durable goods as well.

Read MoreSequential Hard/Soft Injection Molding with Water Assist

In 2004, the value of pairing two-material injection with water assist was demonstrated in production of two-layer automotive pipes and ducts (see Learn More). Further potential for this combination of advanced techniques in sequential injection of hollow automotive parts with rigid and flexible sections is being developed at the German Institute of Plastics Processing (known as the IKV). Water injection technology (WIT) was first developed at the IKV in the 1990s.

Read MoreInjection Molding Compounders Molders Get Control Of Their Materials

The combination of an injection molding press and a twin-screw compounding extruder represents a new paradigm for processors: They create their own materials as they mold them.

Read More