Injection Molding

Engel Opens West Coast Tech Center

Injection machine supplier Engel North America, York, Pa., has opened a new 7300-sq-ft technical center in Corona, Calif., to serve the western U.S.

Read MoreHow to Solve Uneven Clamping

Of the hundreds of variables involved in injection molding, clamping mechanisms and platens often get less attention than they deserve.

Read MoreBetter Purging Saves Money, Material and Time

How much money can a better purging compound save even a small molder?

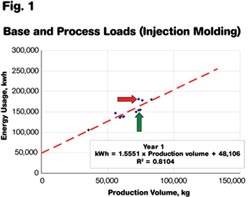

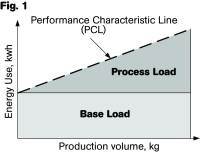

Read MoreInternal Benchmarking: Setting Targets

Last month, we discussed how to graph your plant’s “process energy fingerprint.” Now we’ll show you how to make use of that information.

Read MoreManufacturing Cell for Multicomponent Molding

WEB EXCLUSIVE A new manufacturing cell is designed for production of handles and grips made of multiple materials of different thicknesses that need widely differing cooling times.

Read MoreAdditive Manufacturing: New Capabilities for Rapid Prototypes And Production Parts

Many plastics processors are just starting to become familiar with the terms “additive manufacturing” or “additive fabrication,” which refer to a group of processes that build up parts by successively adding material, often in layers.

Read MoreKnow Your Plant’s ‘Energy Fingerprint’

It is commonly thought that energy use in plastics processing is fixed and uncontrollable.

Read MoreWhy Not Just Let ’r Leak?

Here’s how a typical West Coast molding facility with 20 injection presses investigated the downtime impact of water leaks in the plant.

Read MoreIntroduction to Energy Management For Plastics Processors

Energy efficiency is one of the “hot” topics of the 21st century and plastics processors around the world are trying to come to terms with it.

Read MoreModular ‘Adaptable Automation’ Makes IML More Economical

Five years ago, in-mold labeling was just gaining traction among North American injection molders as a one-step approach to decorating without secondary operations.

Read More